Mar03

Procurement? Meticulously structured. Spreadsheets, approvals, supplier negotiations—the works. Getting shiny new servers into a data centre is a well-rehearsed symphony. Forward logistics? Seamless. Orders placed, assets tracked, everything arriving at its designated rack on time.

But what happens after?

Where do the old machines go—the ones still operational, but replaced by newer, faster, shinier iterations? Stacked in storage rooms? Scrapped too early? Left collecting dust?

Here’s the reality: Reverse logistics is an afterthought in most enterprises. IT asset management? Disjointed, reactive, and alarmingly inefficient. Millions of euros in valuable technology—discarded, misplaced, forgotten.

And it’s not just about sunk costs. The problem scales. The numbers boggle the mind: 62 million metric tonnes of electronic waste in 2022 alone, set to increase to 82 million tonnes by 2030 (according to the 2024 Global E-Waste Monitor). Meanwhile, IT infrastructure is on track to consume 20% of global electricity by the end of the decade.

So, why aren’t more companies taking IT asset reuse, refurbishment, and resale seriously?

Servers, routers, data centres—they don’t sip power, they guzzle it. The cloud isn’t floating on air; it’s sitting on concrete, steel, and silicon, pulling electricity at an unprecedented rate. AI, edge computing, hyperscale growth—it all piles onto an already bloated energy footprint.

And yet, much of this demand is driven by outdated, inefficient hardware. Legacy equipment hums away, burning unnecessary kilowatts, long past the point where an upgrade would make more financial and environmental sense.

The solution isn't just upgrading—it’s what happens next. Reverse logistics, done right, ensures that:

Existing assets are repurposed, resold, or reconditioned instead of scrapped.

Energy-efficient hardware replaces outdated systems sooner, lowering operational emissions.

Decommissioned equipment is recycled properly, reclaiming valuable materials instead of contributing to landfill.

The alternative? Short-term thinking that leads to long-term waste.

Beyond sustainability, reverse logistics is a financial play that too many companies are ignoring. The numbers don’t lie:

20–30% savings on IT procurement for organisations that integrate refurbished assets into their infrastructure.

Faster tech refresh cycles without the long lead times and supply chain bottlenecks seen in new hardware procurement.

Avoidance of regulatory penalties, with stricter e-waste laws pushing companies to prove responsible disposal.

Still, many businesses default to disposal over reuse. Why? Lack of visibility. Poor asset tracking. No incentive structures rewarding lifecycle management.

Regulatory bodies are catching on, though. The EU’s WEEE Directive and Right to Repair laws are shifting the burden, ensuring that manufacturers—and, increasingly, enterprises—take accountability for asset reuse and disposal.

Reverse logistics is messy. Unpredictable. A logistical Rubik’s cube. Unlike forward logistics—where assets move along a clear, linear path—reverse logistics forks in multiple directions.

Where does a decommissioned server go?

This complexity is why AI and predictive analytics are changing the game.

AI-driven asset tracking ensures that every piece of IT hardware is accounted for—where it is, how much life it has left, and whether it should be resold, refurbished, or scrapped.

Machine learning-powered triage evaluates condition, streamlining decision-making on redeployment vs. disposal.

Blockchain-backed chain of custody tracking ensures compliance with evolving regulations, minimising risk and maximising value.

And the result? Companies regain control of their IT inventory, ensuring nothing is wasted, forgotten, or disposed of prematurely.

Some of the biggest names in the industry are leaning into reverse logistics hard:

Cisco: Their Takeback Programme ensures that 99.9% of returned hardware is reused or recycled.

HP: A Certified Pre-Owned IT Programme keeps assets in circulation, reducing demand for new production.

Dell: Their Asset Recovery Services allow companies to return old hardware for resale, reuse, or responsible recycling.

Apple: Their Certified Refurbished program ensured 12.8M devices and accessories were sent to new owners in 2023

The shift toward circularity isn’t just a sustainability play—it’s a strategic advantage.

If reverse logistics isn't on your company’s radar, it needs to be. Here’s how businesses can start making the shift:

Audit Your Existing IT Assets. Know what you have, where it is, and what condition it's in. IT Asset Management (ITAM) tools are critical here.

Establish a Formal Reverse Logistics Process. No more ad-hoc decommissioning. Set up structured workflows for redeployment, resale, and recycling.

Leverage AI & Automation. Asset tracking, condition analysis, and lifecycle optimisation must be data-driven to be scalable.

Work with Certified ITAD Partners. IT Asset Disposition (ITAD) vendors ensure compliance, proper recycling, and maximum value recovery.

For too long, reverse logistics has been ignored—seen as a back-office problem rather than a strategic opportunity. But with IT infrastructure’s energy consumption spiralling, sustainability mandates tightening, and AI reshaping supply chain efficiencies, companies that fail to optimise reverse logistics risk falling behind—both financially and environmentally.

The path forward? Structured, data-driven asset management that prioritises reuse over disposal. Companies that embrace circular IT strategies will cut costs, improve sustainability, and gain resilience in an increasingly volatile supply chain landscape.

Want to go deeper? I spoke with Shannon Payne, SVP of Supply Chain Solutions at MDSi, about how businesses can rethink reverse logistics, harness AI for smarter asset management, and reduce IT’s ballooning energy footprint. Listen to the full episode here.

Article first published on TomRaftery.com. Photo Credit Rwanda Green Fund on Flickr

By Tom Raftery

Keywords: AI, Supply Chain, Sustainability

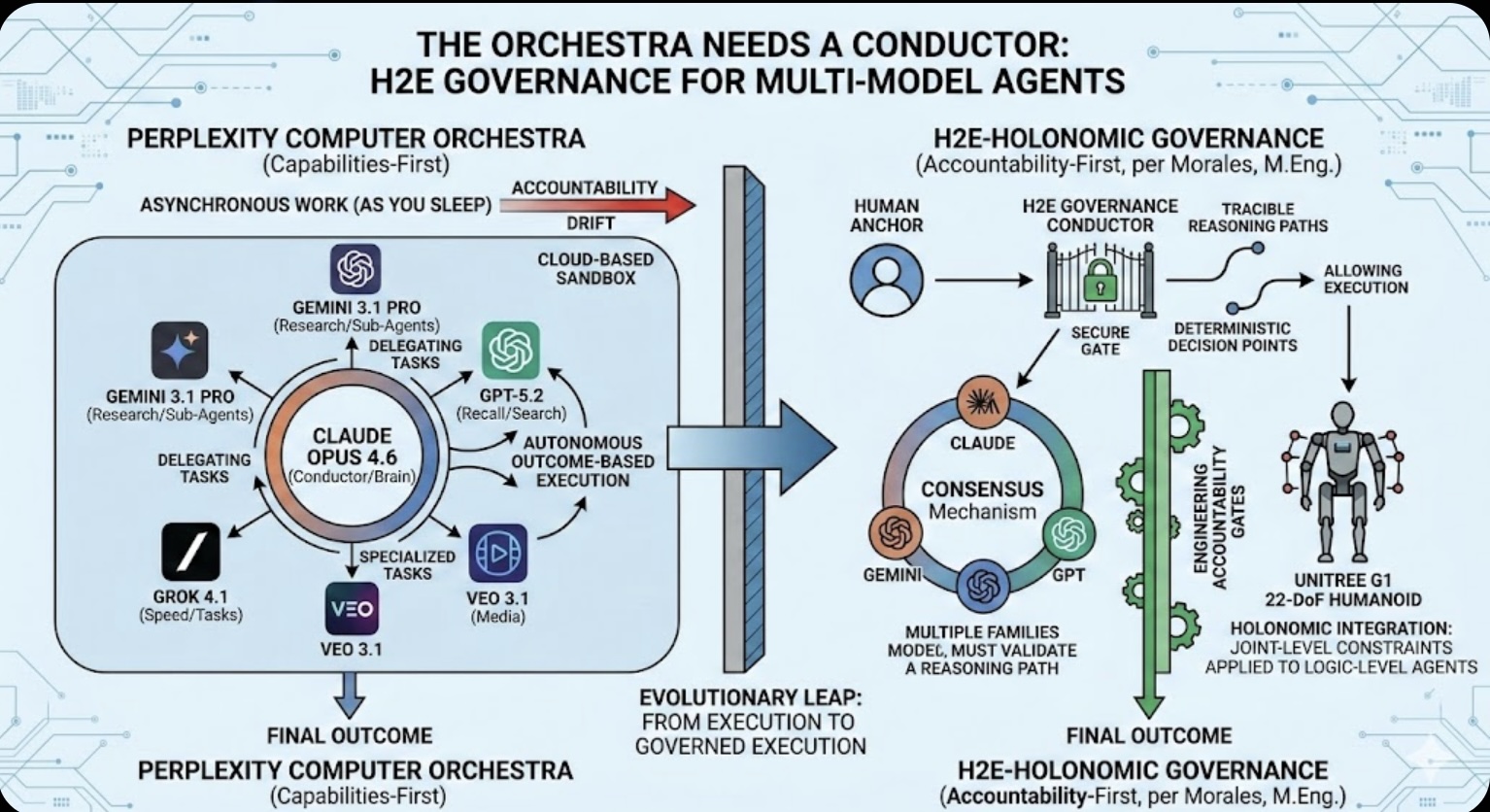

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

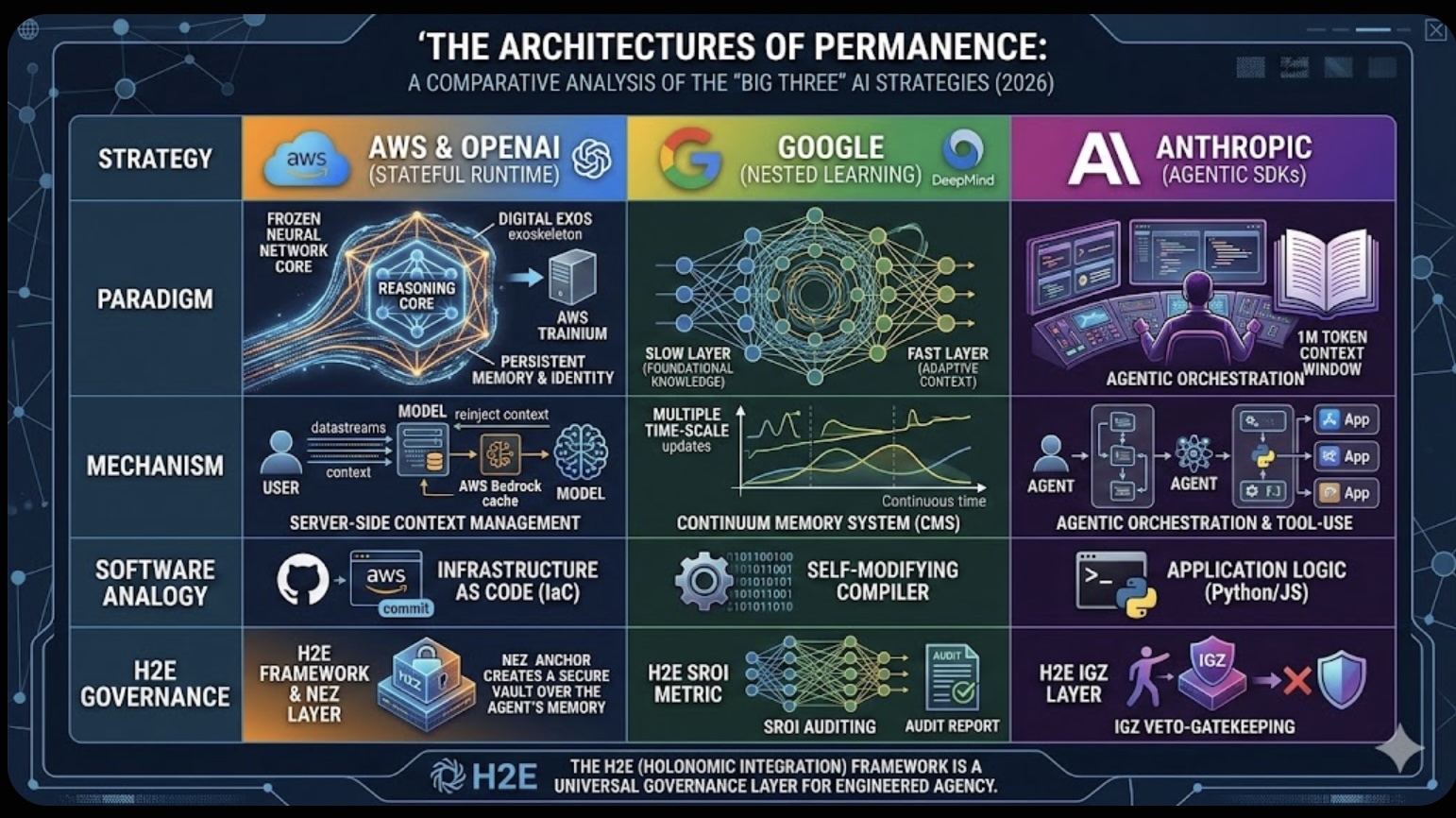

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

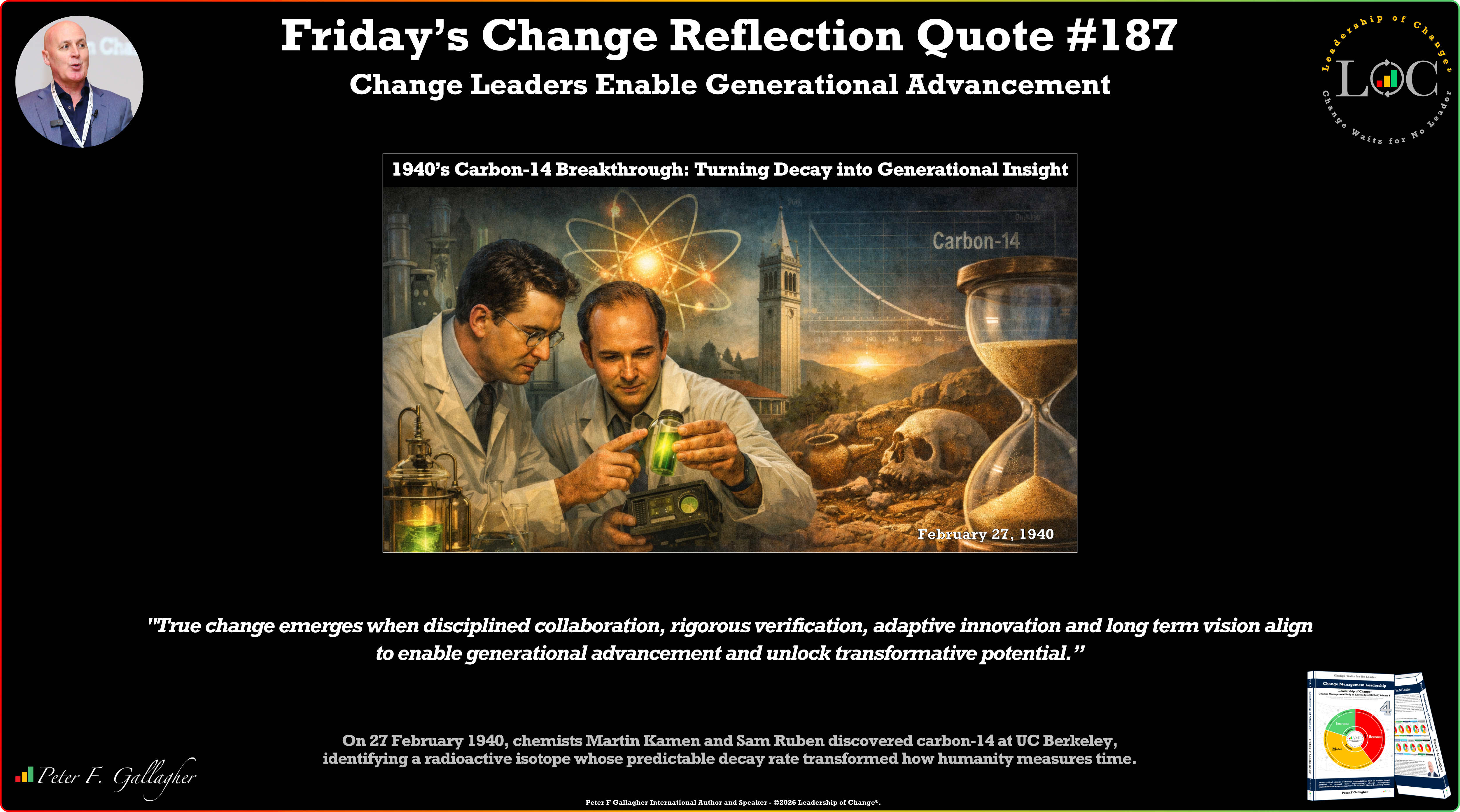

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026