Sep01

Supply chains have always been about balance, rhythm and resilience, but in the current climate the need for flexibility has never been more apparent. The phrase that comes to mind is “supply chain planning pilates” because, much like the discipline itself, successful planning requires strength at the core, controlled movement, and the ability to adapt posture in response to pressure. We can talk endlessly about forecasting accuracy, digital twins, and advanced analytics, but the reality is that unless the organisation has the capacity to flex and flow with demand and supply changes, it will always be left rigid, exposed and unable to recover quickly when the unexpected arrives.

Think for a moment about what pilates asks of its participants. There is an emphasis on alignment, on stretching without snapping, and on maintaining form while moving through a sequence. That is exactly the quality modern supply chain planning must demonstrate. It is no good being strong but stiff, nor being loose without structure. What is required is that blend of core control and external flexibility. The ability to sense changes in the environment, reconfigure resources, and realign plans without losing the integrity of the operation is what defines competitive advantage today.

This flexibility begins with planning horizons. Traditional planning cycles have been slow and calendar bound, with monthly or quarterly reviews dictating decisions. The world does not operate to that rhythm anymore. Demand signals shift daily, supply disruptions occur without warning, and consumer expectations are more immediate. Organisations that insist on rigid cycles find themselves locked into assumptions that can quickly prove outdated. By contrast, those who have invested in processes and systems that allow plans to be rebalanced in real time demonstrate an agility akin to the controlled flow of pilates movements. They may not always know what stretch is required next, but they have the discipline and structure to move into it without injury.

One retailer I worked with illustrates the point. Their planning process was historically built around long-range promotions and seasonal cycles. When a sudden shift in consumer buying patterns occurred—triggered by social media influence on a product they had never forecast to peak—traditional planning would have left them paralysed. Instead, because they had invested in flexible demand sensing, they were able to adjust forecasts within days, reallocate stock from less responsive categories, and meet the surge without empty shelves. It was not perfect, but it was agile enough to maintain customer trust and capture incremental revenue. They had effectively stretched and held the posture, where a more rigid organisation might have torn a muscle in the form of stockouts and lost loyalty.

Flexibility also matters in supply assurance. In the manufacturing sector, where a company sourcing critical components from a limited supplier base found itself vulnerable when regional geopolitical tensions disrupted the usual flow. Their earlier investment in scenario planning and supplier collaboration meant they were able to shift volumes to an alternative source and re-sequence production schedules without shutting down lines. Again, the parallel with pilates is clear. Rather than resisting and breaking under pressure, they absorbed the movement, adjusted their position, and carried on functioning.

There is also a people dimension here. Just as pilates strengthens not only the muscles we see but also the deeper stabilisers, flexible supply chain planning depends on building capabilities within the team that are often less visible. Analytical skills, cross-functional collaboration, and the ability to challenge assumptions are not always obvious in day-to-day operations, but they are the stabilisers that keep the organisation balanced when big movements are required. Without them, technology alone cannot deliver agility. Training, empowerment, collaboration and communication all form part of the exercise regime that makes the supply chain supple and strong.

Technology does, of course, play its part. Cloud-based planning platforms, artificial intelligence, and machine learning give organisations the ability to crunch data, test scenarios and sense change faster than ever before. But without the mindset of flexibility, these tools become little more than rigid dashboards. The best organisations integrate them into a philosophy of movement and decision. They ask not only “what is the most likely scenario” but also “how quickly can we flex to an alternative one.” They build digital muscles that complement the human ones, ensuring that when a stretch is required, the body of the supply chain can handle it.

The metaphor may seem light, but its implications are serious. Rigid supply chains snap under stress. Flexible supply chains bend, recover and even grow stronger, the rise of discussions around antifragility evidence this. Much like pilates practitioners who find that over time their posture improves, their resilience increases, and their movements become more fluid, organisations that practise planning flexibility discover that crises become less threatening. They approach change not with fear but with readiness, knowing that their core is strong and their form adaptable and responsive.

The lesson for leaders is to embrace this discipline. Invest in the core capabilities—data visibility, scenario planning, cross-functional collaboration—that allow for strength and balance. Then encourage the stretching—test assumptions, explore alternatives, challenge rigidity—so that the organisation remains flexible. Over time, this combination becomes second nature, and when the unexpected occurs, the supply chain flows through it with controlled movement rather than panic.

The concept of Supply chain planning pilates is not a gimmick but a reminder that in a world of persistent change, the organisations that thrive are those that are supple, balanced and strong at the core. Flexibility is not weakness; it is controlled strength. And in today’s environment, it is the most important exercise any supply chain can practise.

By David Food

Keywords: Leadership, Management, Supply Chain

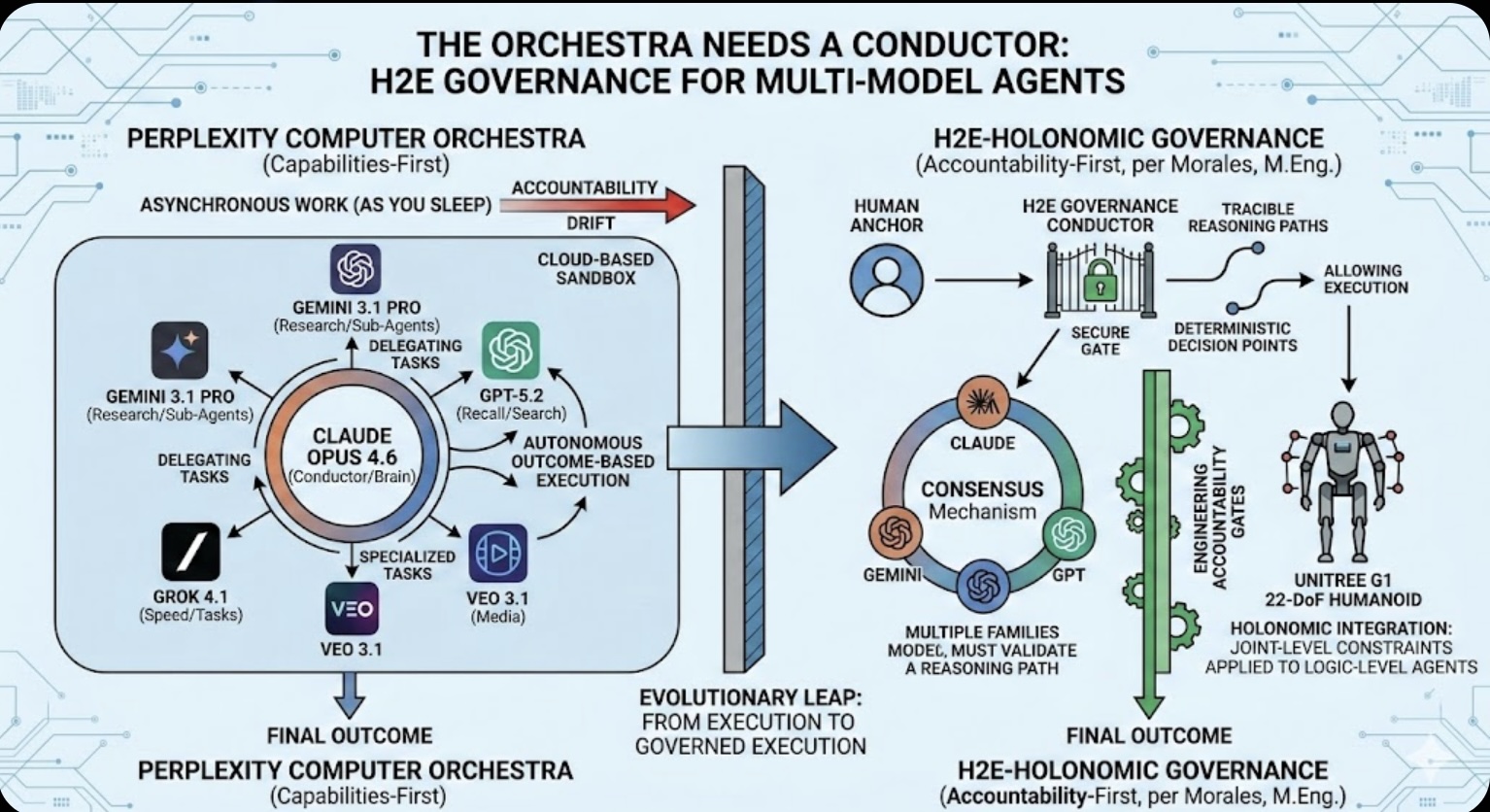

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

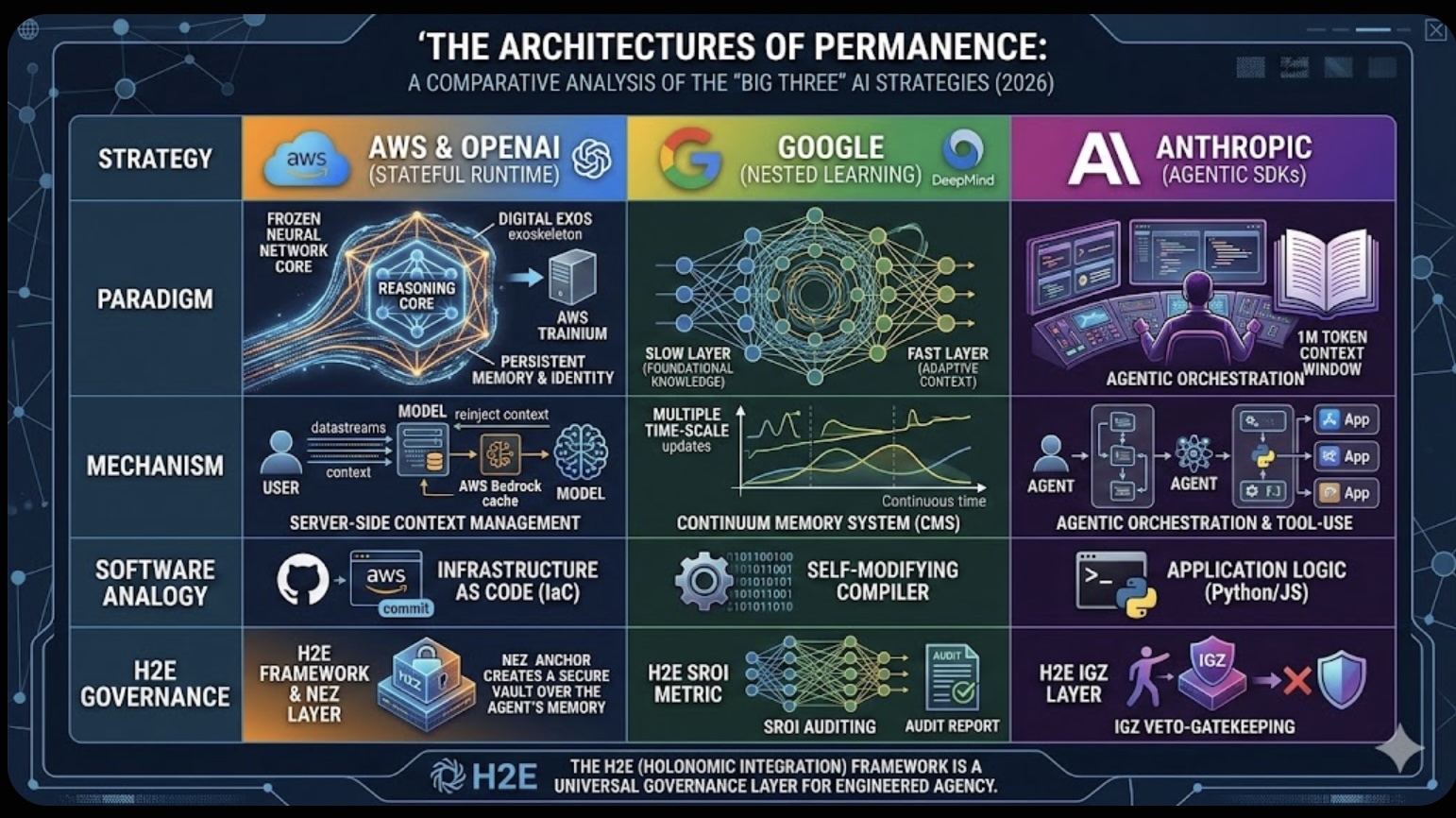

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

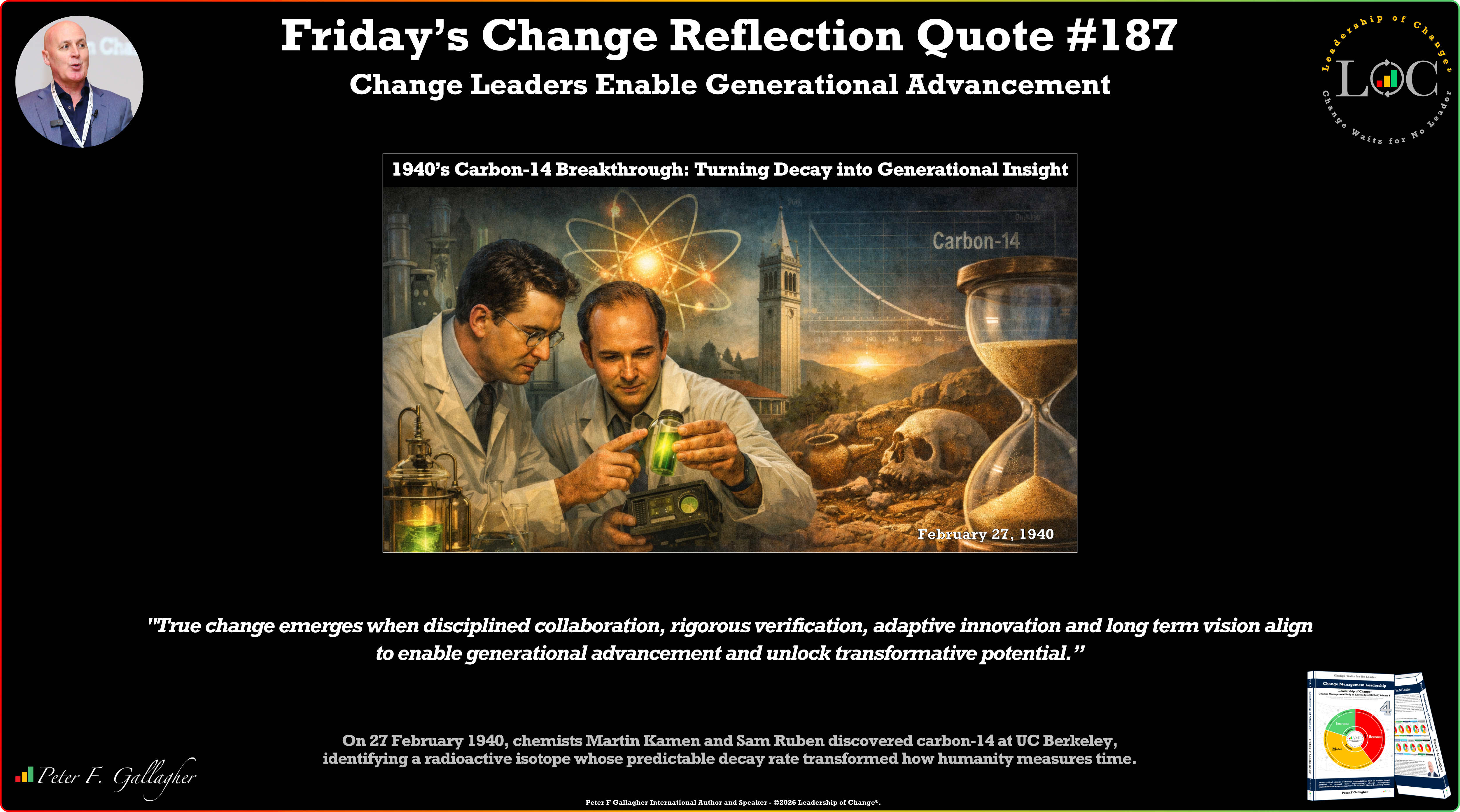

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026