Aug15

If you run a global supply chain in 2025, you’re standing at the intersection of unprecedented pressure and unprecedented possibility. On one hand, the science is unambiguous: supply chains account for anywhere from 60% to 90% of global corporate greenhouse gas emissions, depending on the sector. They are also a major generator of waste, from unsold products to inefficient packaging and unnecessary freight miles. On the other, we now have the technology to measure, optimise, and systematically decarbonise those very systems at a scale unimaginable a decade ago.

Yet here’s the uncomfortable truth: while we’ve known for 20 years that supply chains are the lever, we’ve largely failed to pull it hard enough. The climate clock hasn’t stopped ticking - the IPCC warns we need to halve global emissions by 2030 to avoid the worst impacts of warming, and the market is shifting under our feet. The EU’s Corporate Sustainability Reporting Directive (CSRD) and Carbon Border Adjustment Mechanism (CBAM) are already reshaping procurement decisions far beyond Europe’s borders. If your goods cross an EU border, these rules are your reality.

The good news? With the right blend of technology, data, and AI, you can turn sustainability from a compliance headache into a competitive weapon.

The numbers speak for themselves. McKinsey research shows that for consumer goods companies, over 80% of emissions are Scope 3, largely embedded in upstream suppliers. And the CDP estimates that supply chain emissions are on average 11.4 times higher than operational emissions. Waste is equally staggering - the UN Food and Agriculture Organization estimates that 14% of the world’s food is lost before it even reaches the retail stage, much of it due to poor forecasting, inefficient logistics, and mismatched demand.

You can’t manage what you can’t measure, and for most companies, Scope 3 measurement has historically been fragmented at best, guesswork or ignored at worst. That’s changing fast thanks to new technologies.

The first pillar of transformation is visibility. Internet of Things (IoT) devices, embedded in everything from factory machinery to shipping containers, are generating real-time, granular data on production processes, transport conditions, and inventory flows.

Consider Maersk’s remote container management system - every refrigerated container is IoT-enabled, allowing real-time monitoring of temperature and humidity. That’s not just operationally efficient; it reduces spoilage, cuts waste, and lowers emissions by avoiding emergency shipments.

Digital twins, virtual replicas of physical supply chains, are the next layer. Unilever has built digital twins of manufacturing sites to model energy use and material flows, identifying optimisation opportunities without touching the real-world plant. The result: targeted upgrades with faster ROI, and fewer costly mistakes.

And integration is key. Too many companies still have sustainability and supply chain data trapped in silos. As Saskia van Gendt from Blue Yonder noted in our recent conversation, the leaders are those creating shared, cross-functional visibility so that a supply chain routing decision is instantly visible in carbon terms, not months later in a sustainability report.

Once you have the data, AI can do what humans can’t: process vast datasets at speed, spot patterns, and continuously optimise complex systems.

Forecasting accuracy is one of the most immediate wins. Blue Yonder’s AI-powered demand planning tools have helped companies like Bayer Crop Sciences cut over a million unnecessary transport miles in South America — fewer miles means lower fuel use, fewer emissions, and reduced costs.

AI also enables carbon-aware planning. Imagine being able to choose suppliers not just on cost and lead time, but on real-time carbon intensity, factoring in the day’s energy mix in a manufacturing location. In Spain, for example, the grid can swing from 80% renewable one day to 40% the next. AI can match production schedules to cleaner energy windows, or reallocate orders to plants with lower-carbon power.

But AI isn’t a silver bullet. It’s only as good as the data it’s fed, which is why IoT and integrated systems are indispensable. AI also consumes energy, and the sustainability balance sheet must net positive. That means running models efficiently and, where possible, on low-carbon data centres.

CSRD and CBAM are game-changers. Under CSRD, some 50,000 companies will be required to report detailed Scope 1, 2, and 3 emissions, along with transition plans, starting this year. CBAM will apply a carbon price to imported goods like steel, cement, and fertilisers based on their embedded emissions.

These aren’t just European concerns. If you export to the EU, your carbon accounting is now a trade issue. As Saskia pointed out, carbon intensity of national grids varies wildly, and shifting sourcing due to tariffs or politics can inadvertently raise your footprint. Companies that have real-time data on supplier emissions will avoid costly surprises, and may even turn low-carbon sourcing into a differentiator.

Waste isn’t just an environmental problem, it’s a balance sheet issue. Inventory write-offs, returns processing, and disposal costs are all forms of value destruction.

Technology can close the loop:

Circularity isn’t a CSR add-on. The Ellen MacArthur Foundation estimates it could generate $4.5 trillion in economic benefits by 2030 through reduced material use, waste, and energy.

One of the most important cultural shifts is the alignment of sustainability and supply chain teams. In too many organisations, these groups operate in parallel, one tracking emissions for reporting, the other making operational decisions without full carbon context.

Leaders are creating joint KPIs, shared data platforms, and incentive alignment. A grocery retailer Saskia worked with set departmental-level carbon reduction mandates; the supply chain team could see exactly how a routing change or supplier choice moved the needle against their 60,000-ton reduction target. That’s accountability with teeth.

From my perspective, and echoed by Saskia, leaders share five traits:

Laggards, by contrast, are still reporting Scope 3 emissions using industry averages and annual spreadsheets, and making decisions blind to carbon consequences.

Decarbonising and de-wasting your supply chain isn’t just about avoiding penalties or meeting ESG targets. It’s about resilience, cost control, and future market position.

If you’re leading supply chain, energy, or sustainability strategy, here’s where to start:

The companies that start now will have the systems, relationships, and market credibility to thrive in a low-carbon economy. The ones that delay will find themselves scrambling under regulatory, investor, and customer pressure.

As Saskia put it: “The time to act was 20 years ago, but the next best time to act is right now.” We have the tools, the data, and the AI to cut millions of tonnes of CO₂ and millions of tonnes of waste out of global supply chains. The question is whether we’ll use them decisively enough, soon enough.

If you want to hear more from Saskia van Gendt on how Blue Yonder is integrating sustainability into supply chain technology, including specific customer examples and deeper dives into AI use cases, I recommend listening to the full episode of the Sustainable Supply Chain Podcast here.

And don’t just listen. Audit your data, evaluate your tech stack, and set a clear roadmap for cutting emissions and waste now. Because in supply chains, as in climate action, those who move first will define the market the rest have to follow.

This article first appeared on TomRaftery.com. Photo credit Señor Codo on Flickr

By Tom Raftery

Keywords: AI, Supply Chain, Sustainability

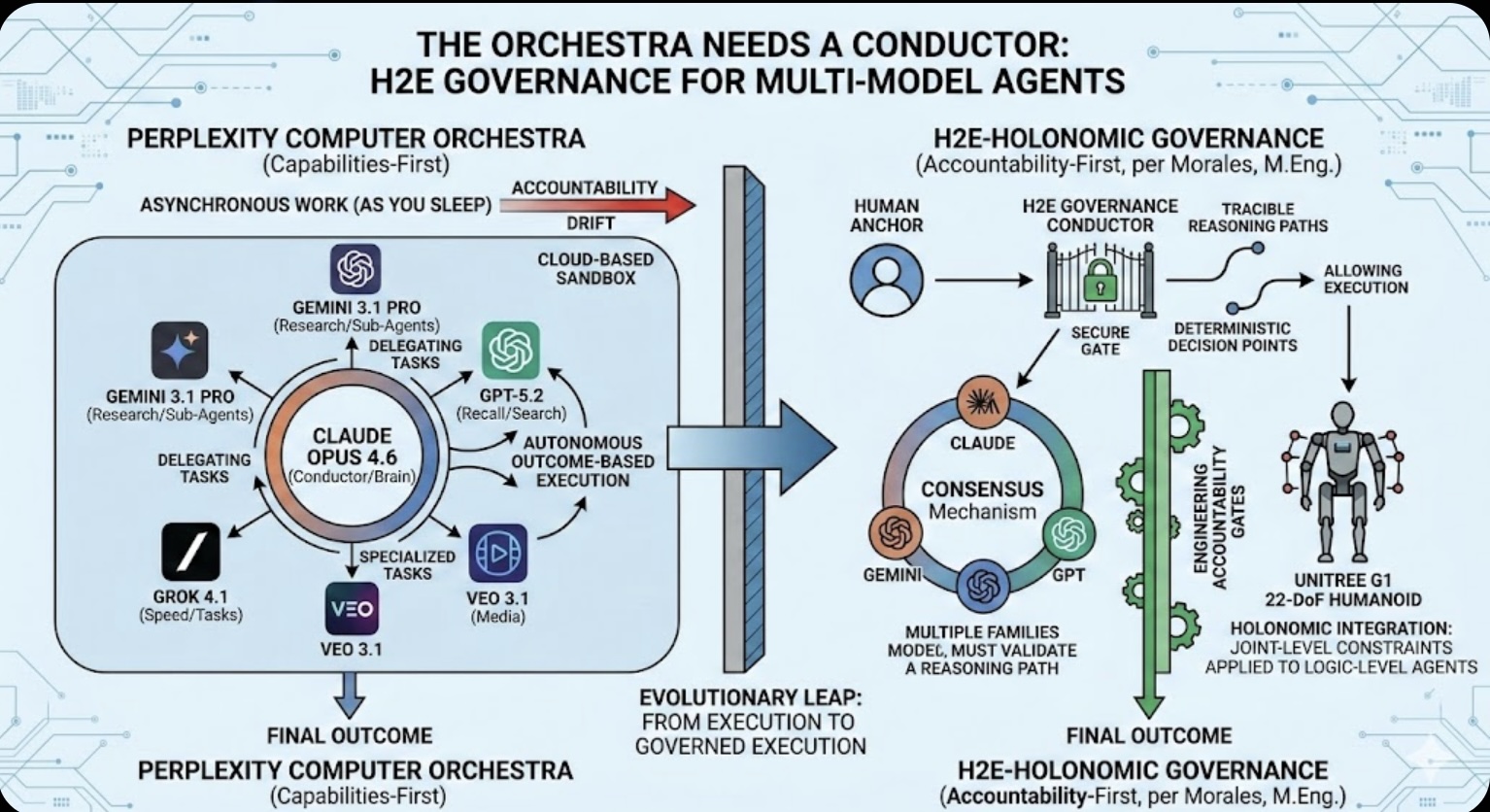

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

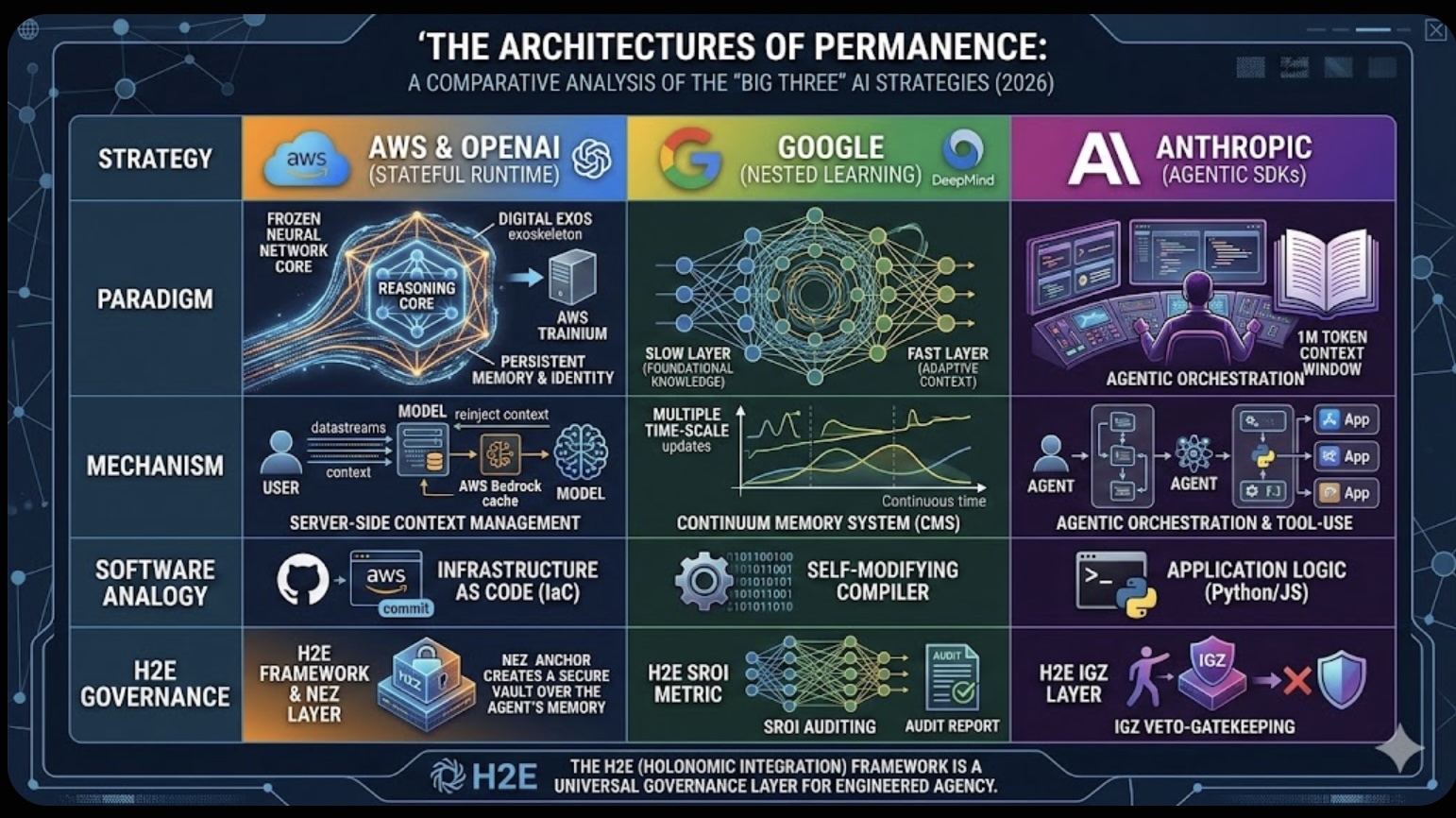

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

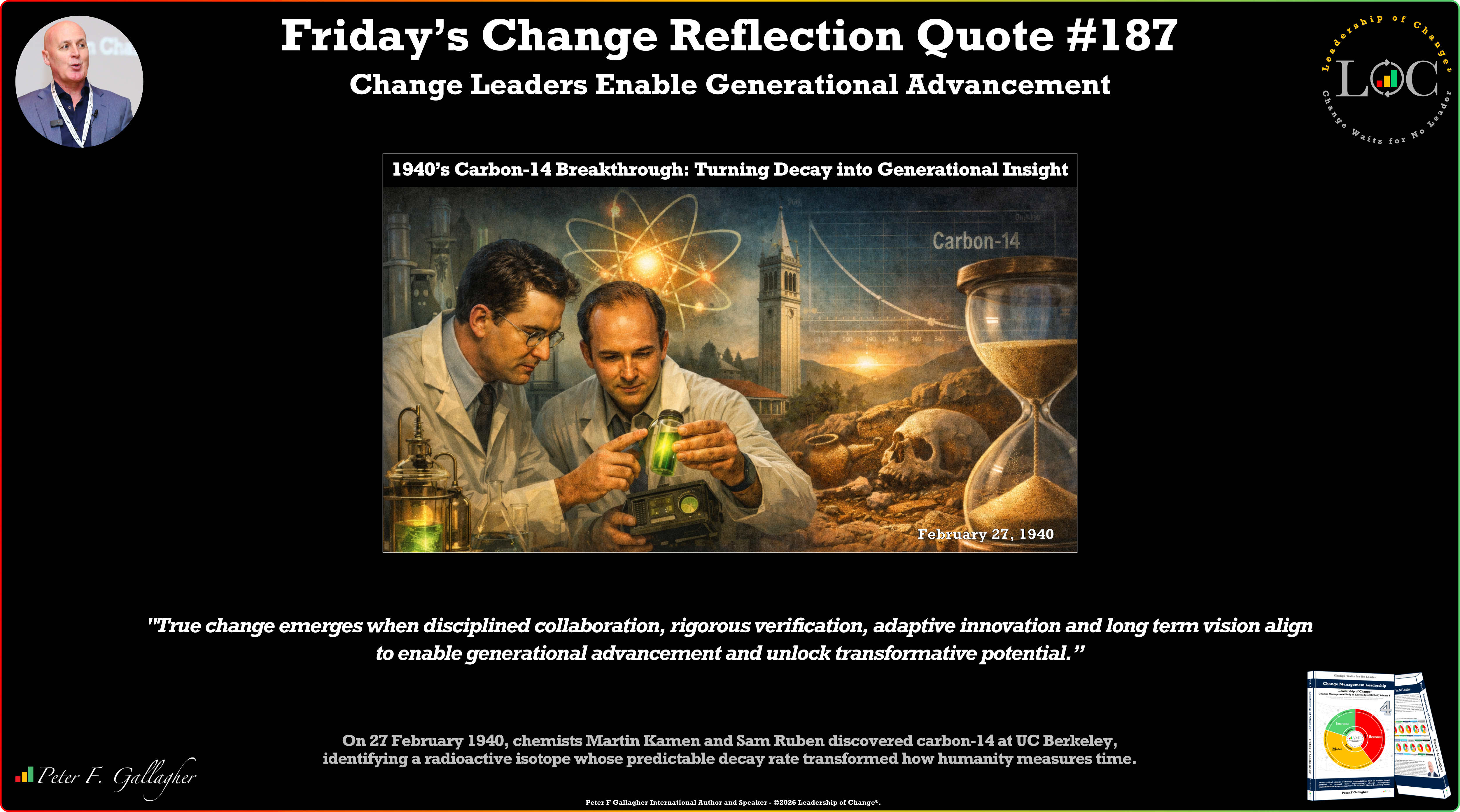

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026