Jun17

Artificial Intelligence is increasingly becoming part of the fabric of everyday business life, and in the world of supply chain management, its influence is already reshaping how we approach some of the most complex challenges. One such area experiencing profound change is replenishment planning. As someone who has spent decades observing the evolving dynamics of planning and logistics, I find it both encouraging and cautionary to consider how AI is being used in this space — and more importantly, how it should be used.

Replenishment planning has always been a critical function within the supply chain. Its role — ensuring the right products are in the right place at the right time — sounds simple enough on the surface, but anyone involved in the process knows the sheer number of variables, constraints, and human behaviours that complicate the task. Traditional methods relied heavily on spreadsheets, rule-based systems, and the accumulated experience of planners. These methods were not necessarily broken, but they were often reactive and cumbersome. Forecast inaccuracies, promotional distortions, seasonality shifts, and supply variability made the job one of ongoing firefighting.

With AI, we now have the tools to move from reactive to proactive, from static to dynamic, and from gut-feel to data-led decision making. Machine learning algorithms, for example, are being trained to identify patterns across vast amounts of historical data. These models don’t just produce a more refined forecast — they adjust to changes in demand behaviour, learn from anomalies, and continuously improve over time. Rather than being bound by preset rules, AI systems adapt to nuance, which is especially valuable in sectors like FMCG where volatility is the norm rather than the exception.

But it’s not just about forecasting. AI plays a key role in shaping the replenishment decisions themselves. It can evaluate multiple factors — lead times, supplier reliability, logistics capacities, inventory policies, customer service levels, and even weather data — to recommend optimal reorder quantities. It can flag when a promotion is likely to distort the replenishment pattern or when a stockout risk is emerging before the data becomes obvious to human planners. In essence, AI is providing planners with a level of foresight and granularity that was previously impossible to achieve at scale.

It is a mistake to think of AI as a magic wand. Despite the extraordinary advances, AI systems are only as good as the data they are fed and the governance structures around their use. In replenishment, context still matters. Human judgment, local knowledge, and commercial instincts remain essential. The challenge is to bring together the best of both worlds — to create systems where AI augments rather than replaces the planner. This isn’t about choosing between people and machines. It’s about recognising that the future of replenishment planning lies in collaboration between the two.

Collaboration needs to be built on trust. For planners to embrace AI recommendations, they need to understand them. Black-box algorithms, no matter how powerful, breed suspicion when their outputs can’t be explained. This is where the role of explainable AI becomes critical. Transparency in how decisions are made allows planners to engage with the system, not just observe it. It also fosters accountability — a necessary safeguard in a discipline where wrong decisions can have significant downstream impacts.

The integration of AI into replenishment planning is not without growing pains. There are issues of organisational readiness, data quality, skills gaps, and cultural resistance. Yet the direction of travel is clear. Those businesses that are willing to invest in the right systems, the right people, and the right mindset are already seeing returns, not only in inventory performance but in the resilience and agility of their supply chains. They are moving faster, making smarter decisions, and responding more effectively to change, beating the competition.

As with all technological advances, the question is not whether AI will be used, but how wisely. We must be deliberate in ensuring that our use of AI in replenishment planning serves the broader purpose of sustainable, customer-focused supply chains. We must also ensure that the human element is never lost in the process. After all, the best plans — whether driven by people or powered by algorithms — are those that combine intelligence with wisdom.

By David Food

Keywords: Agile, AR/VR, Supply Chain

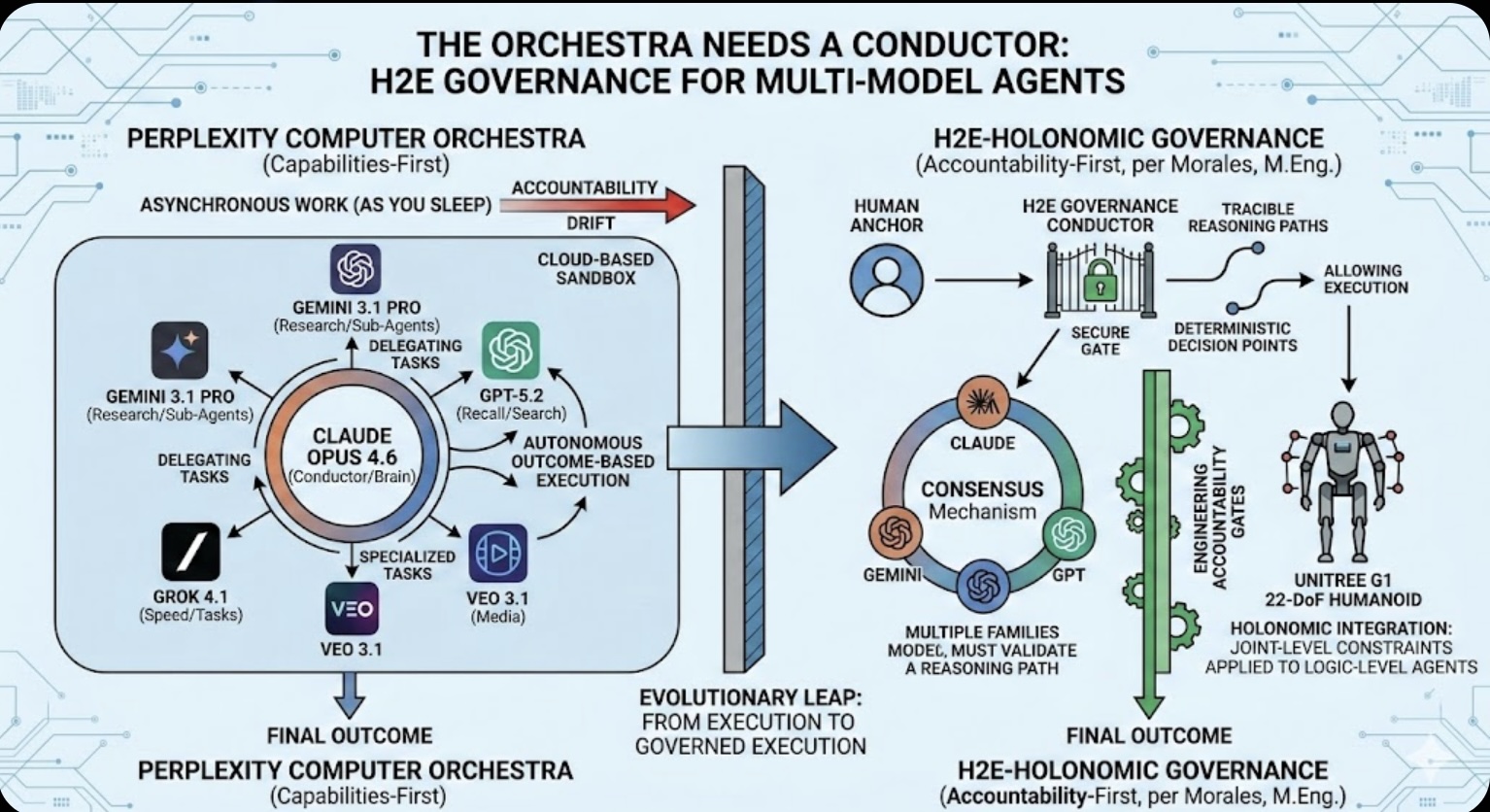

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

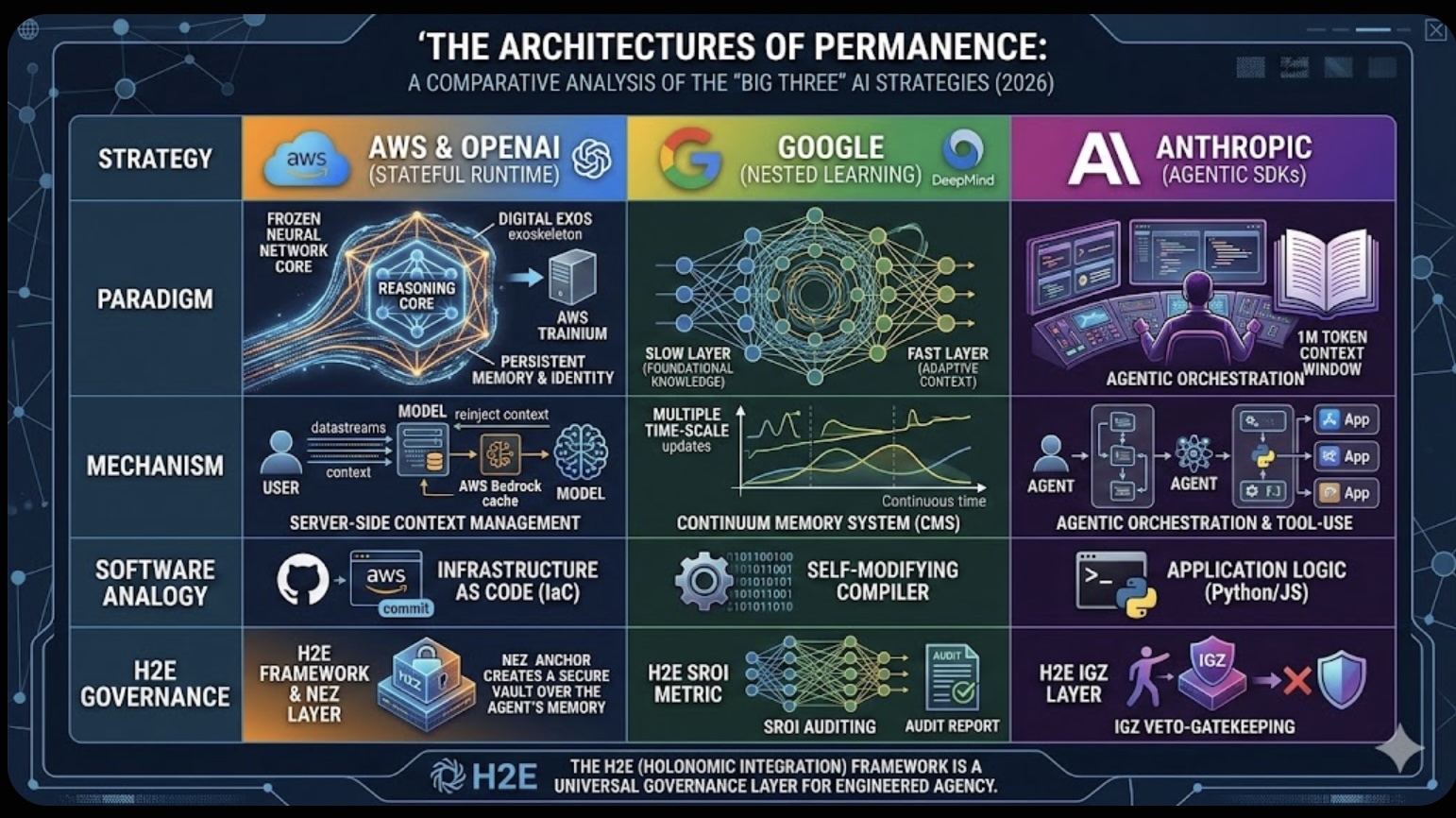

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

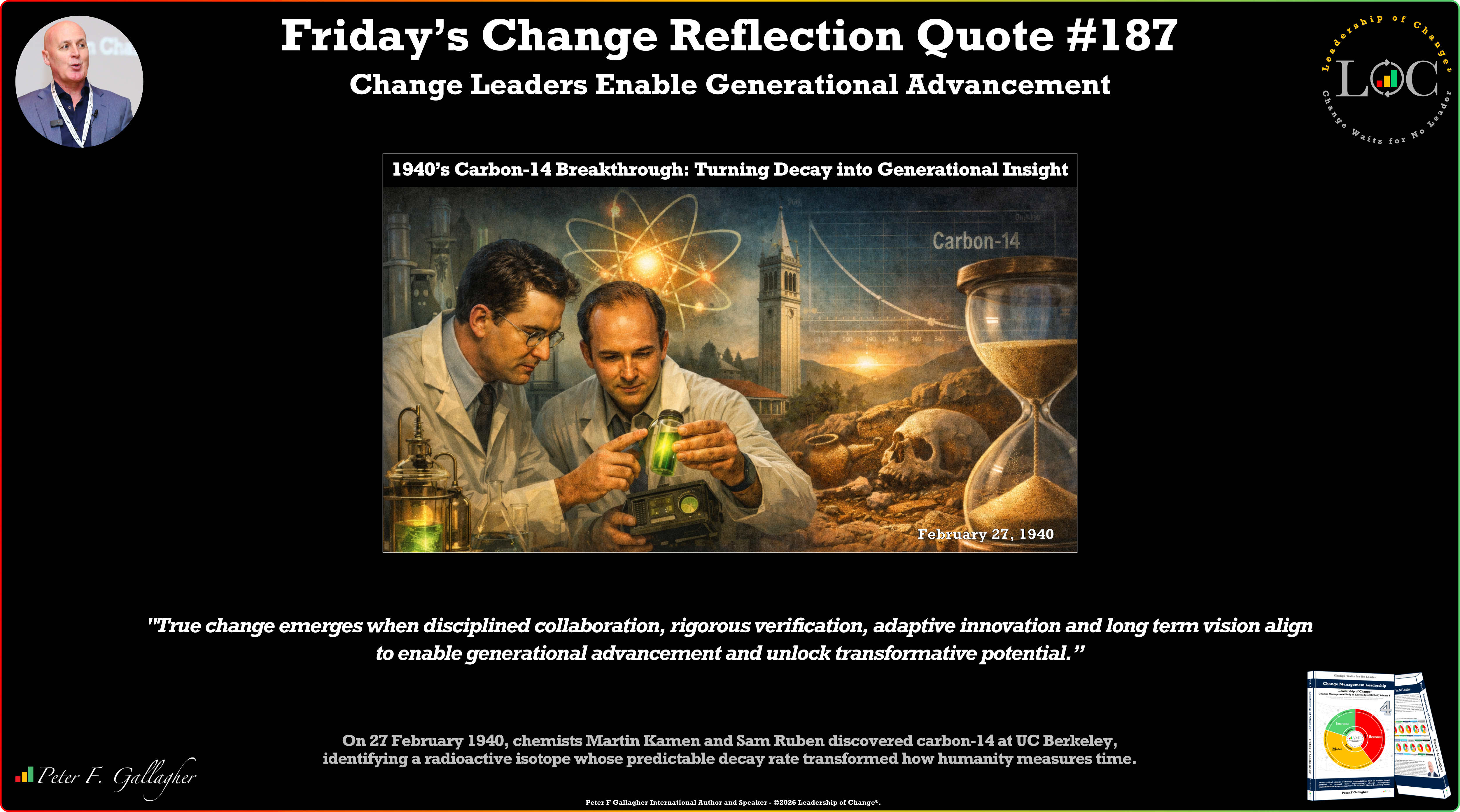

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026