May15

As an MEP Procurement Manager in high-pressure construction projects, I’ve learned that risk is not a disruption—it’s a direction.

In the world of building systems—HVAC, electrical panels, sanitary equipment—the smallest delay can stall entire site sequences. Add global supply constraints, technical dependencies, and strict delivery milestones, and procurement becomes a race against uncertainty.

But risk analysis isn't a defensive move. It’s a strategic tool.

By structuring a proactive procurement risk framework, we can:

Map supply chain exposure against project timelines

Identify long-lead and compliance-critical items early (e.g., switchboards, chillers)

Develop RFQs around risk tiers, not just product specs

Hold suppliers accountable through milestone-driven contracts

Align procurement with site logistics, engineering approvals, and commissioning phases

In MEP procurement, timing is everything. And structured risk analysis gives us the foresight to make smarter calls, not just faster ones.

When procurement is treated as an engine for control, clarity, and resilience, risk stops being a threat—and becomes the reason we succeed.

By Athina Tsoni

Keywords: Construction, Procurement, Risk Management

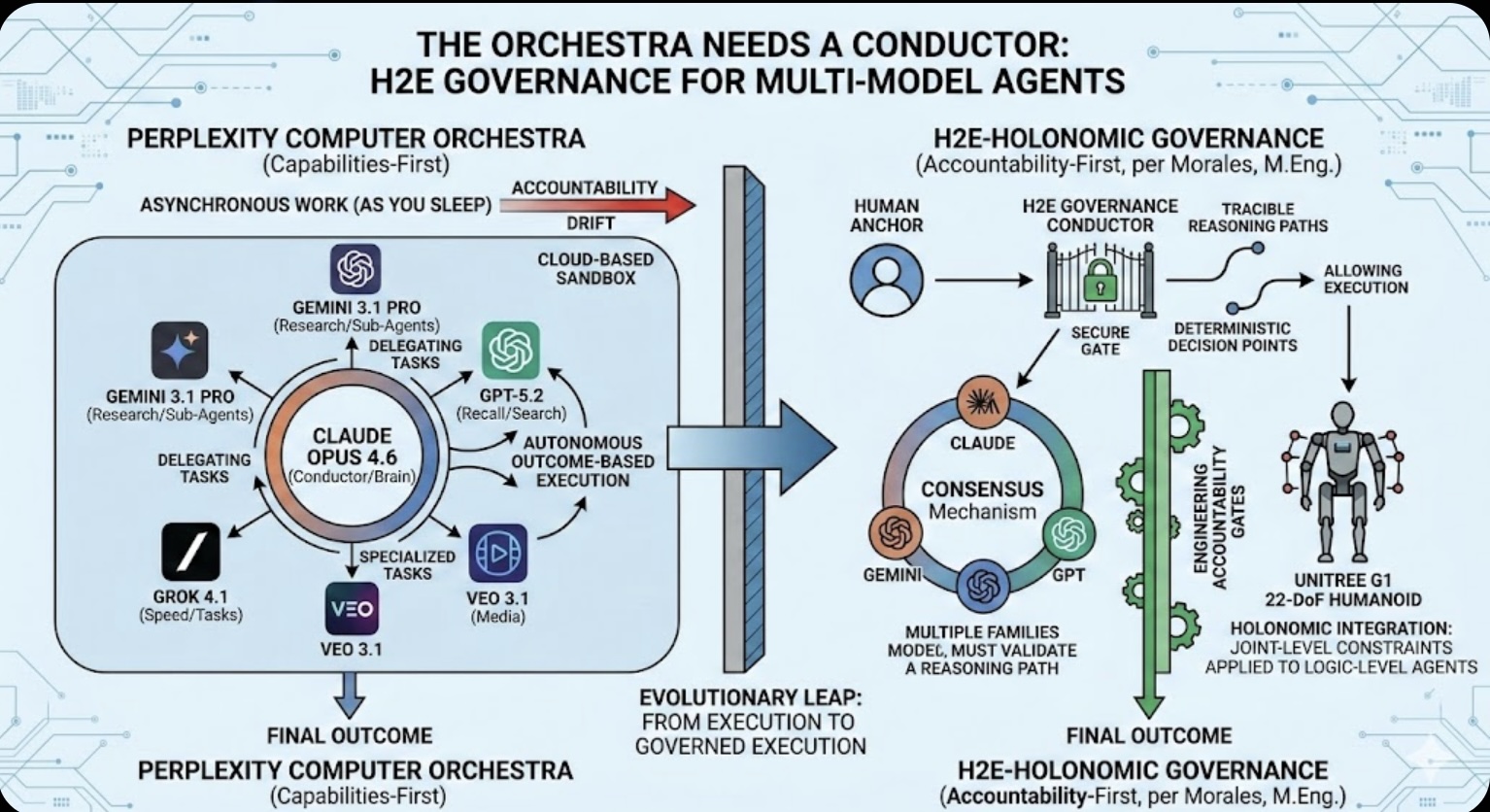

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

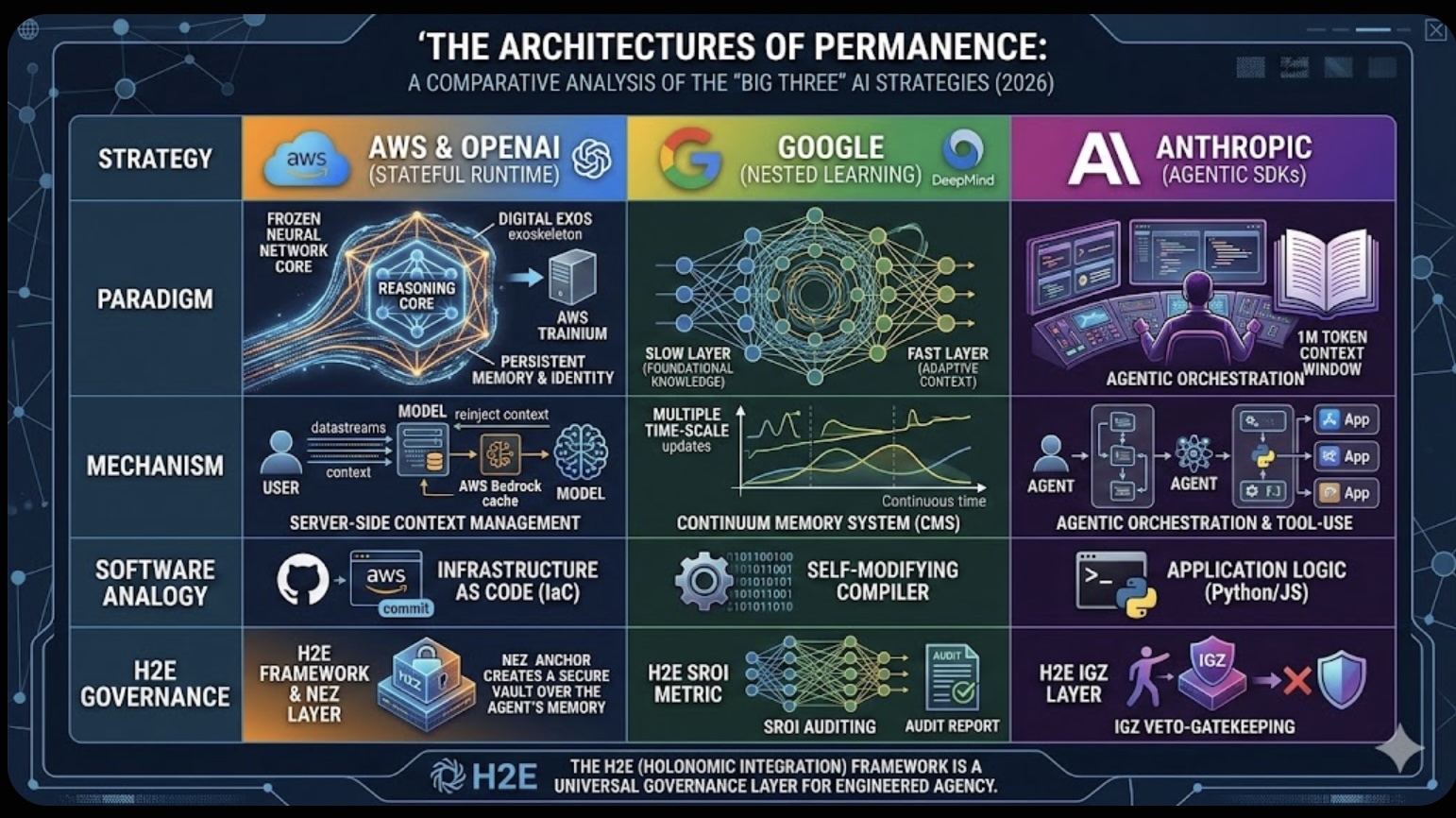

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

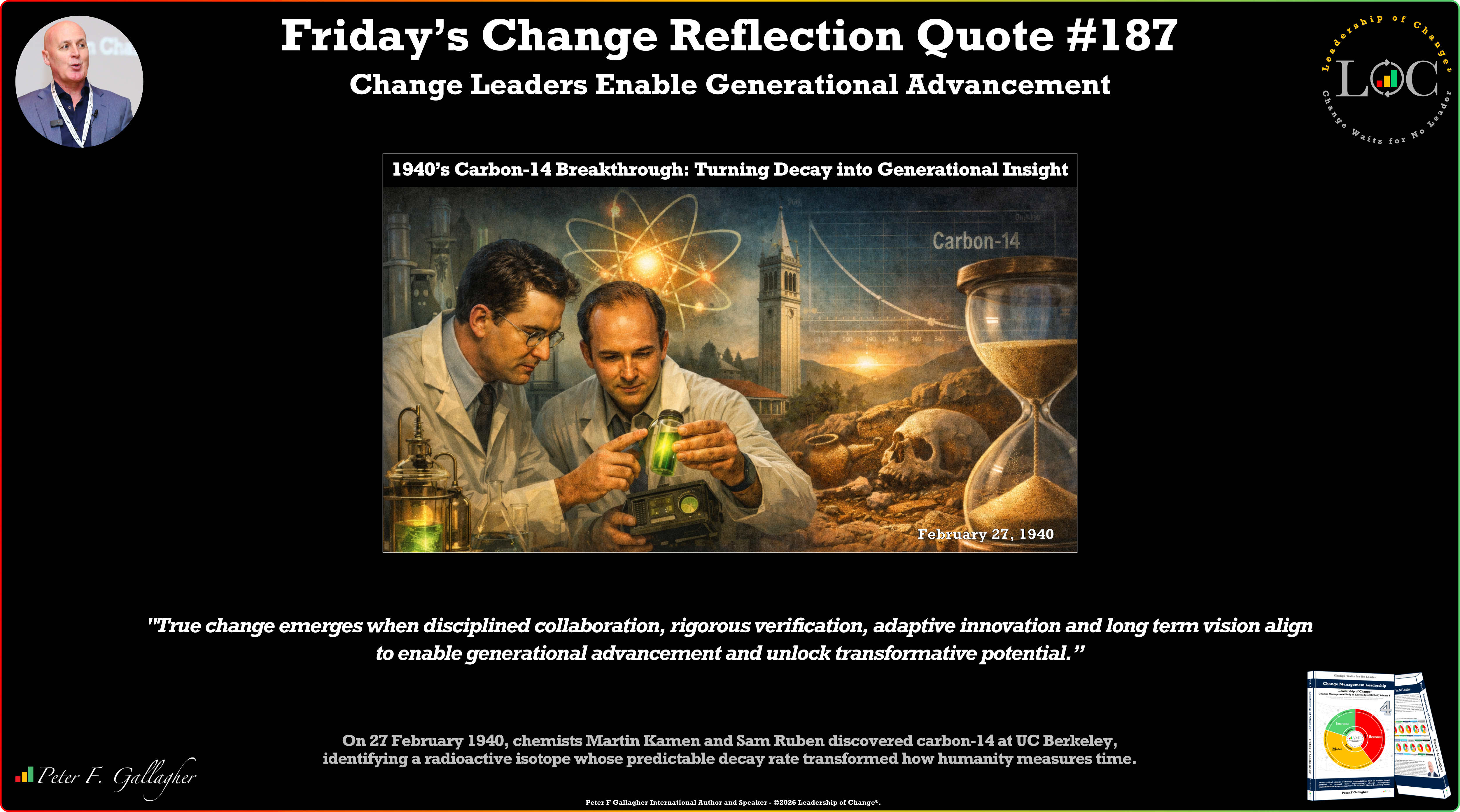

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026