Dec02

You know when you go into the kitchen and you’re hungry and you open the cupboard and there’s a tin of beans just waiting there? Or when you walk into the supermarket and the shelves are full of crisps and bananas and milk and bread, even though nobody you know works in a banana plantation? That doesn’t just happen by magic, though it might look like it. Behind the scenes, there are people called supply chain planners, and their job is a bit like being the conductor of a very large, very noisy orchestra where half the musicians have gone on holiday and the other half have changed their instruments without telling you.

I used to do something like that for a living. Not the orchestra, sadly, though I did once play the triangle at school, but the planning. Imagine you’re having a birthday party. You want balloons, cake, drinks, plates, a clown, and possibly a spare clown if the first one gets lost. You don’t want the balloons to arrive after the party or the cake to turn up a week before and go stale. You also don’t want to spend all your pocket money on too many crisps nobody eats. So you make a list, work out when things need to be bought, and keep checking that the shop still has everything. That’s planning. Now multiply that by a thousand products, a hundred countries, several lorry drivers, a few boats, some trains, and a cloud of spreadsheets, and you’ve got the job of a supply chain planner.

They start by guessing – well, forecasting, which sounds posher. They look at what people have bought before, at the seasons, at promotions, at weather forecasts, and try to work out how many boxes of cereal or packets of biscuits might be wanted in two weeks, two months, or even a year. This is a bit like trying to predict how many sprouts the family will eat at Christmas. You know roughly, but Auntie Mabel might suddenly become vegan or your cousin might bring a friend who eats like a horse. That’s where the planner’s skill comes in: reading patterns, spotting surprises, and not panicking when the sprouts go unsold.

Once they’ve got an idea of demand, planners work with suppliers and factories to make sure enough is produced, packed, and shipped. They juggle lead times, production schedules, and transport options. Sometimes the goods are on the other side of the world, on a ship that might be delayed by storms or blocked canals. Sometimes the lorry driver is off sick or the warehouse is full. Planners have to think ahead, line up alternatives, and keep everything moving. They’re like those people spinning plates on sticks, only with more emails.

And there’s a lot of talking. You might think planners sit quietly at desks with calculators, but really, they’re on the phone or in meetings, explaining why there aren’t enough biscuits or why there are suddenly far too many. They coordinate between salespeople who want everything now, finance teams who want to spend nothing at all, and operations teams who are trying to fit one more pallet into a warehouse already bursting at the seams. They have to be a bit diplomatic, a bit firm, and occasionally funny, otherwise everyone just shouts. Think of it as being the referee in a family board game, but with more spreadsheets and fewer tears, hopefully.

Of course, things go wrong. Ships get stuck, factories break down, customers change their minds. A good planner doesn’t just make a plan; they make a plan B and a plan C. They build in a little spare stock, a little extra time, or a backup supplier. They don’t always get it right – nobody can – but they get very good at reacting quickly. It’s not about predicting the future perfectly; it’s about being ready when the future does something odd, like a cat walking across the jigsaw you’ve been doing for hours.

So when you see a shelf full of chocolate bars, or your online order arriving the next day, think of the planners. They’re behind the scenes, working out how much to order, where to store it, how to move it, and what to do when half of it’s delayed. They’re part detective, part mathematician, part juggler, and part magician. Without them, the world would be a lot emptier and your sandwiches might be just bread. It’s not glamorous, and it’s not magic, but it’s clever, caring work that keeps everything ticking. And that, my dears, is what I did, though sometimes I still wish I’d stuck with the triangle.

By David Food

Keywords: Leadership, Supply Chain, Transformation

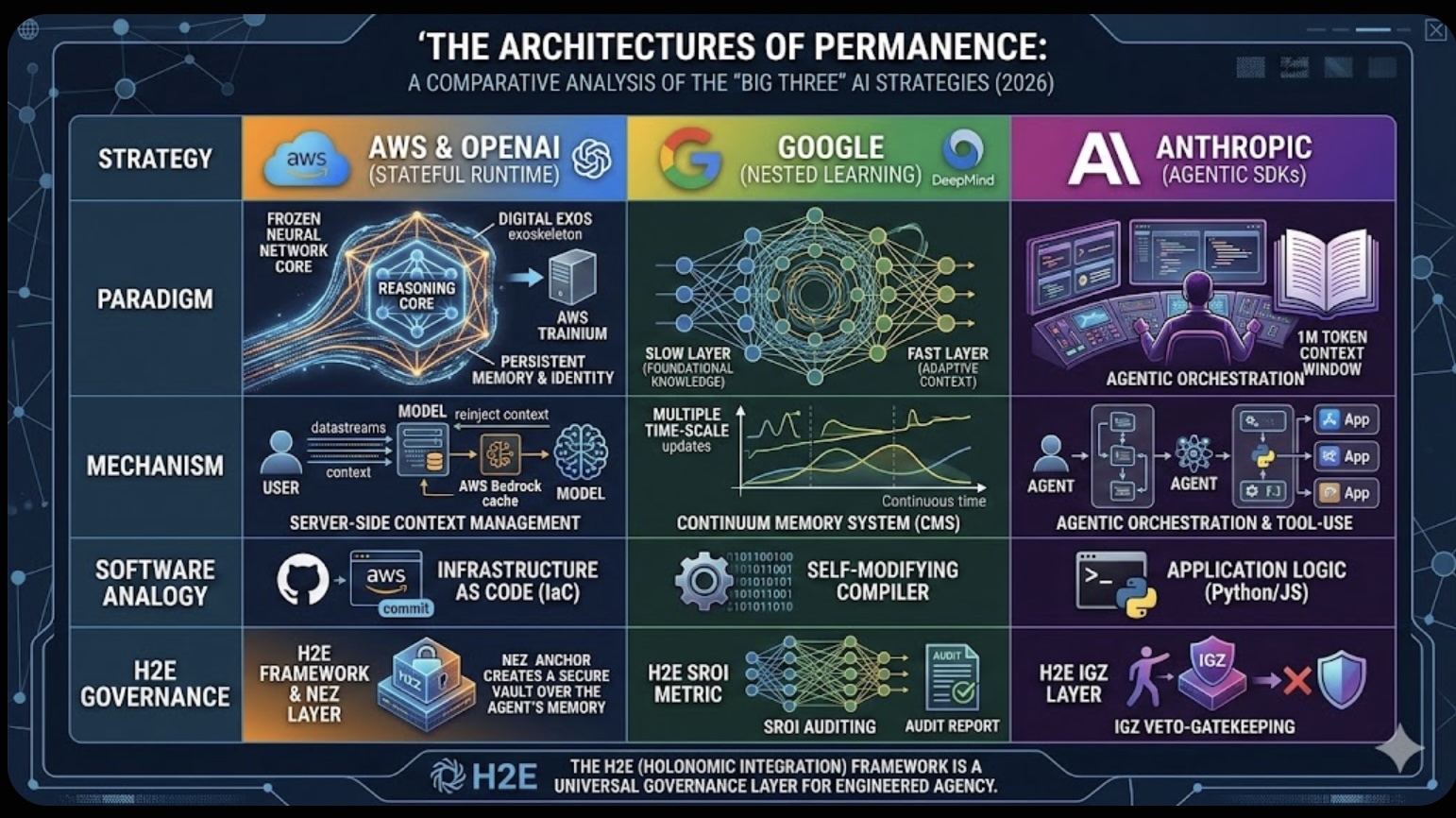

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026 What Leaders Should Be Losing Sleep Over (But Aren’t)

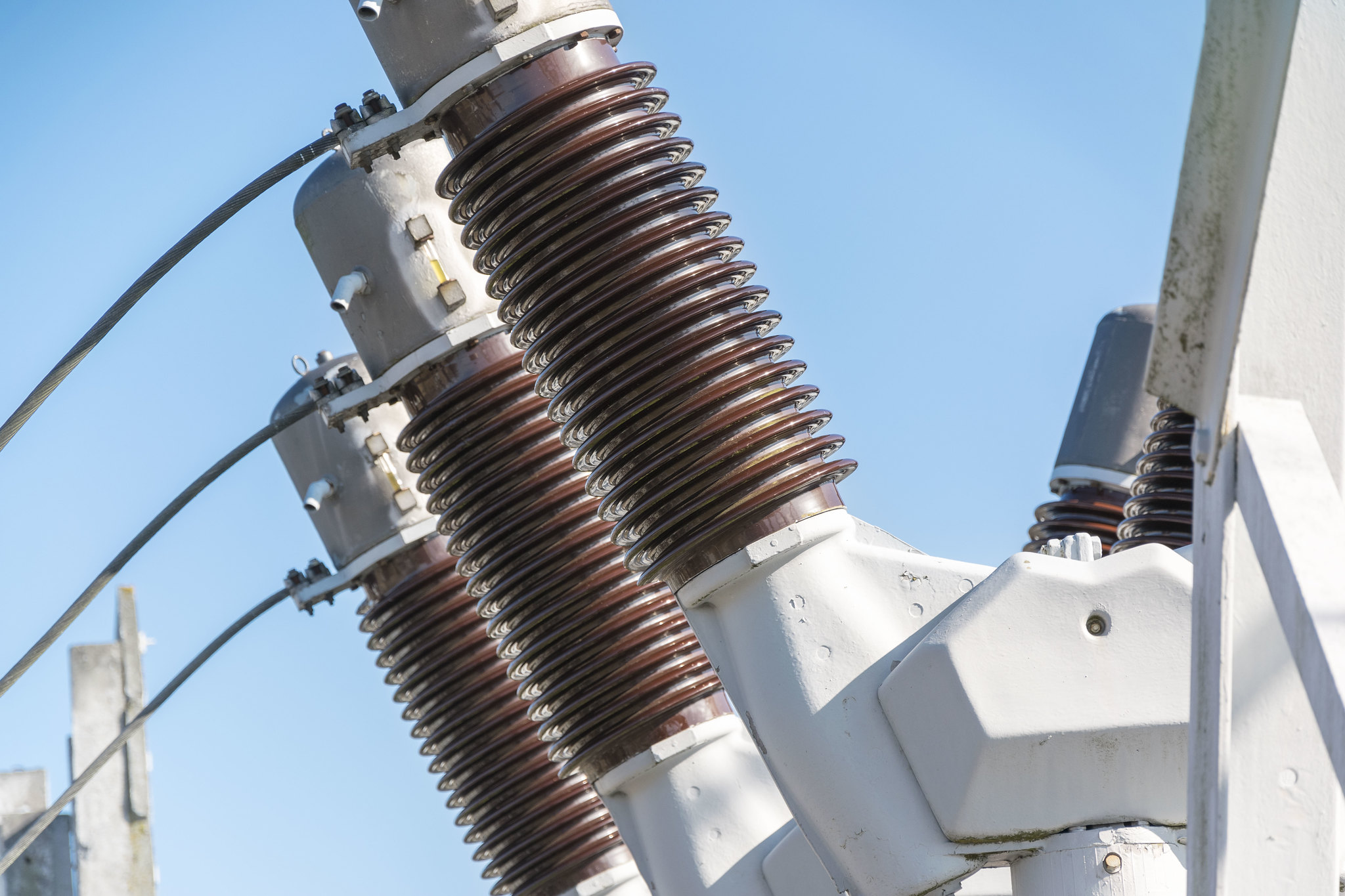

What Leaders Should Be Losing Sleep Over (But Aren’t) Energy System Resilience: Lessons Europe Must Learn from Ukraine

Energy System Resilience: Lessons Europe Must Learn from Ukraine