Oct29

Supply chain planning remains one of the most persistent enigmas in modern business. Even with decades of technological advances, from the first Material Requirements Planning systems to today’s machine learning algorithms, organisations still struggle to align supply and demand in a world where volatility has become normal. The challenge is not simply the complexity of networks or the unpredictability of markets; it is also the cultural and behavioural dynamics that sit beneath the process. As the strategist Peter Drucker once observed, “There is nothing so useless as doing efficiently that which should not be done at all,” and nowhere is that more accurate than in planning departments churning out elegant but disconnected outputs.

At its heart, planning is the attempt to synchronise diverse and sometimes competing activities: procurement, production, logistics, and customer fulfilment. Yet too many companies still treat it as a back-office task rather than a strategic capability. The result is fragmented forecasting, conflicting assumptions, and duplicated efforts. Companies invest heavily in new digital platforms, hoping for clarity, but without aligned behaviours and incentives, these tools often digitise old habits rather than transform them. In this sense, the technology gap is closing, but the mindset gap remains wide.

The history of supply chain planning is marked by numerous false dawns. Advanced Planning and Scheduling in the 1990s, collaborative planning in the 2000s, and today’s AI-driven forecasting engines each promised to remove uncertainty and deliver precision. They have undoubtedly improved visibility and speed, yet they have not eliminated the fundamental human challenges of judgement, trust and cross-functional collaboration. Yossi Sheffi has written frequently about the human factor in resilience, noting that “technology can process information, but it cannot provide judgment.” This is precisely why planners remain indispensable, interpreting models, reconciling anomalies and sensing signals that algorithms cannot see.

Forecasting itself is emblematic of the enigma. Managers know that forecasts will never be perfect, yet they persist in measuring success as if perfection were possible. This creates perverse incentives and a misplaced obsession with forecast accuracy rather than organisational agility. The real question is whether the business can adapt when the forecast is wrong. In a world of black swans and grey rhinos, it is not the accuracy of the prediction but the flexibility of the response that defines competitiveness. Planning must therefore evolve from a deterministic process focused on “getting it right” to a dynamic capability focused on “getting ready.”

Achieving this shift demands leadership as much as analytics. Planners need the trust of executives to take informed risks and make rapid adjustments. They also need the humility to listen to colleagues, suppliers and customers, blending quantitative signals with qualitative insights. This is less about solving a mathematical equation and more about conducting an orchestra. A conductor does not play every instrument but ensures harmony among diverse players. Similarly, supply chain planners orchestrate data, capacity and demand across networks to achieve outcomes greater than the sum of the parts.

Data, decisions and dialogue must work together. Data must be timely and accurate, but without context, it remains inert. Decisions must be supported by analytics but not delegated entirely to machines. Dialogue – the continual exchange across functions, suppliers and customers – is what turns abstract plans into operational reality. In volatile markets, it is the speed and quality of these conversations, rather than the precision of the model, that create a competitive advantage. Recent disruptions, from pandemics to geopolitical tensions and climate shocks, have exposed the fragility of extended supply chains and the inadequacy of static plans. The organisations that performed best were not those with the most advanced forecasting systems but those with diversified supply bases, built-in buffers and empowered teams ready to pivot. The military aphorism that “no plan survives first contact with reality” applies directly to supply chains. The true test of planning lies not in how it looks on a dashboard but in how it functions when reality intervenes.

Reframing the enigma means seeing planning not as a quest for perfect prediction but as a discipline of sensing, learning and adapting. It calls for leaders who understand both systems and people, who blend analytics with intuition, and who elevate planning from a procedural necessity to a strategic differentiator. When this happens, planning becomes a source of customer satisfaction, resource stewardship and organisational resilience rather than a perennial headache.

The supply chain planning enigma may never disappear entirely, but it can be progressively mastered. This is not the work of a single project but of a sustained commitment to culture, capability and continuous improvement. The organisations that take this path will not only weather uncertainty but turn it into a competitive advantage. If your business is ready to move beyond forecasting obsession and build true planning agility, start the conversation now, invest in your people and processes, and transform planning into the strategic powerhouse it is meant to be.

By David Food

Keywords: Predictive Analytics, Supply Chain, Transformation

Lateral Moves: The Most Overlooked Succession Strategy in Companies

Lateral Moves: The Most Overlooked Succession Strategy in Companies The Asset Play: Timing, Structure & Global Arbitrage

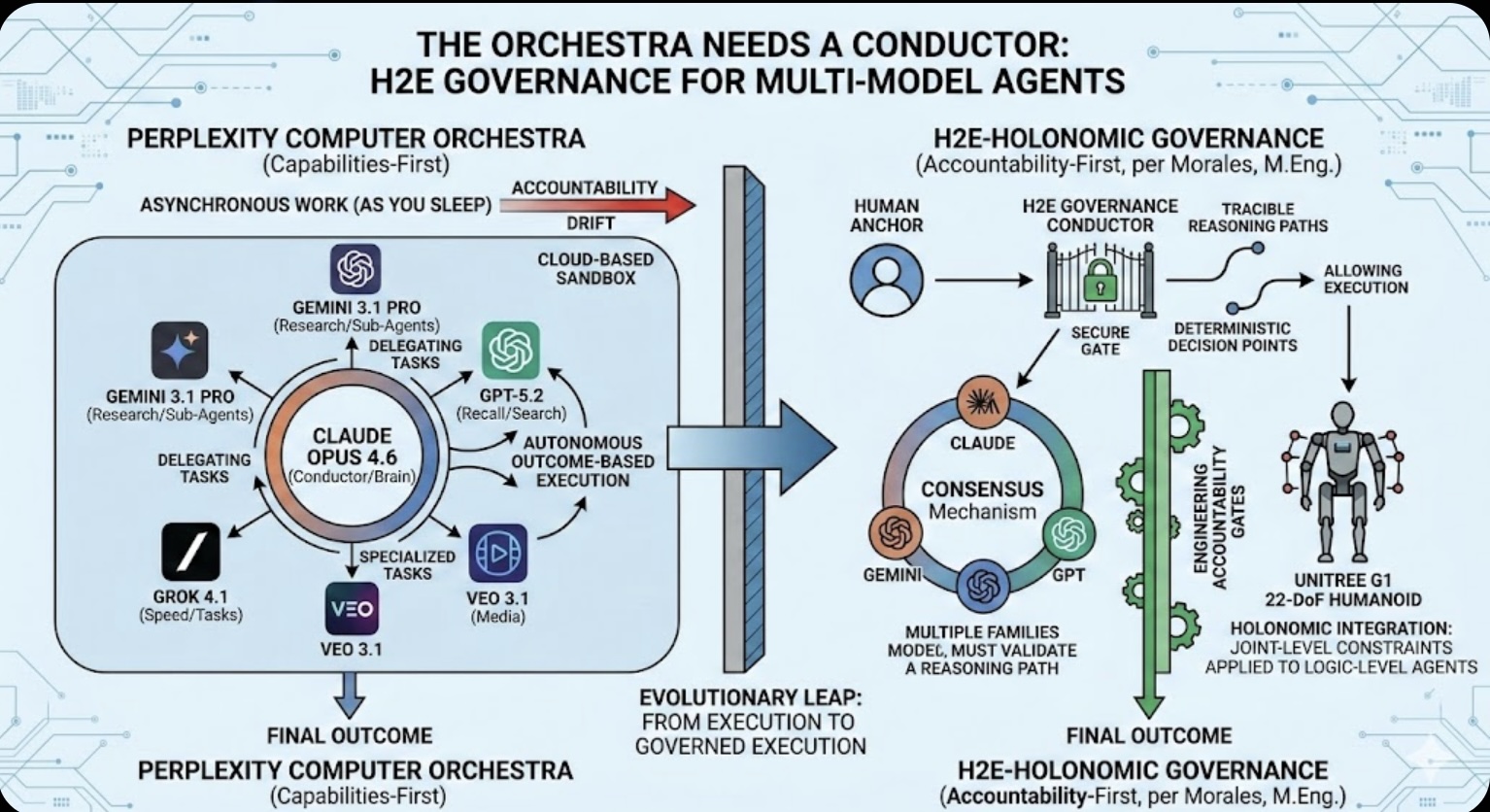

The Asset Play: Timing, Structure & Global Arbitrage  The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

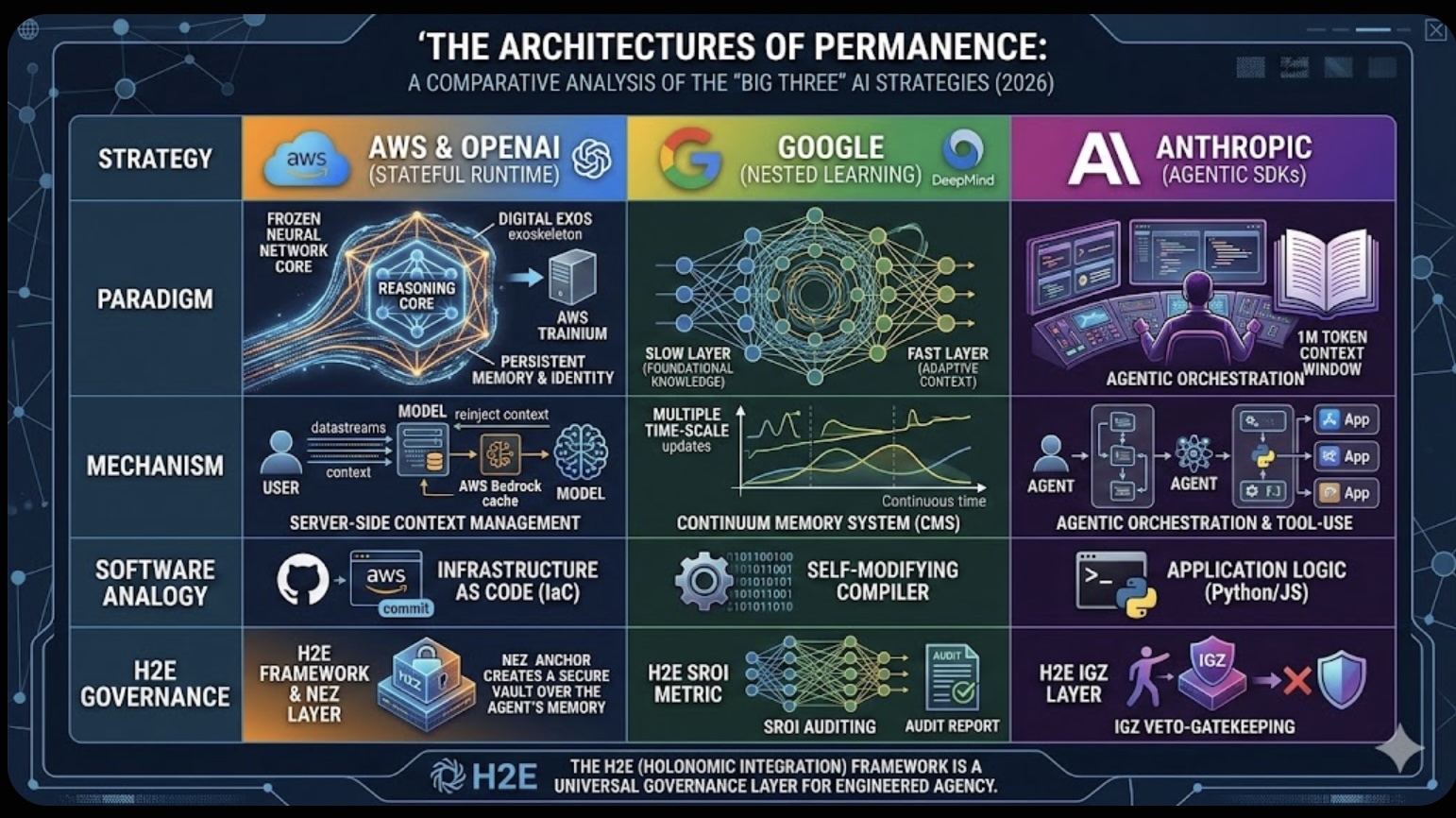

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)