Nov06

roduct portfolio complexity has become one of the defining challenges in a post-COVID world for supply chain management. In almost every sector, companies have expanded their product ranges in the pursuit of growth, customer choice and market segmentation. The logic is compelling: if we can offer more flavours, more pack sizes, more variations, then we will capture more of the market and respond more closely to customer needs. Yet while this strategy may work at the front end in terms of sales and marketing, it carries profound implications for the back end in terms of supply chain planning. What appears to be an incremental extension of range can trigger disproportionately high levels of complexity, variability, waste and cost throughout the chain.

At its heart, supply chain planning is an exercise in balancing demand and supply. It requires us to predict with some confidence what the market will require and to align capacity, inventory and distribution accordingly. The more complex the product portfolio, the harder this balancing act becomes. Forecasting is already challenging in volatile and uncertain markets; when demand is fragmented across hundreds or even thousands of SKUs, each with distinct consumption patterns, forecasting accuracy diminishes further. Small errors at the SKU level accumulate into significant distortions of stockholding, leading to either costly overstocks or damaging stockouts.

Complexity can magnify the bullwhip effect. A small shift in consumer demand for a specific variant is amplified as it moves upstream through the supply chain. Suppliers, faced with uncertain signals and nervous about capacity shortfalls, often overcompensate. The result is an unstable system in which inventory buffers are inflated and responsiveness is impaired. Ironically, in attempting to please the consumer through greater choice, companies often undermine the very reliability and availability that consumers value most.

The operational burden of product portfolio complexity is also considerable. Production scheduling becomes more fragmented as lines must be changed more frequently. Each changeover consumes valuable capacity and introduces the risk of error or downtime. Distribution becomes less efficient as load planning is compromised by the need to carry a wider range of products in smaller volumes. Warehousing costs rise as space and handling requirements increase. Even procurement and supplier relationships are affected as smaller order quantities and more diverse specifications complicate sourcing strategies.

It is important to recognise that complexity itself is not inherently negative. Some complexity is a reflection of genuine market diversity and differentiated customer requirements. Global markets with distinct cultural preferences may necessitate a wider product palette. In premium categories, a proliferation of options can be part of the brand proposition. The danger lies in unmanaged complexity, where product proliferation is driven more by internal enthusiasm or competitive mimicry than by demonstrable customer value. Too often, organisations fail to apply a disciplined lens to range expansion, neglecting to assess the total supply chain cost implications, thereby parking future profitability because of discounting and write-off costs.

From a planning perspective, the challenge is to create visibility and segmentation. Not all products are equal in their contribution to revenue or margin. The classic Pareto principle applies: a relatively small proportion of SKUs typically account for the majority of sales. By identifying and prioritising the critical few, planners can focus resources and forecasting attention where it matters most, while managing the long tail of slower-moving items in a different manner. Advanced planning systems and demand sensing tools offer support here, but they require clean data and clear rules to be effective.

The financial consequences of unmanaged complexity are significant. Inventory is often where the hidden costs accumulate. Stock is tied up in slow-moving SKUs, yet the system still experiences shortages of fast movers. Working capital is consumed unnecessarily, service levels decline, and planners find themselves constantly firefighting. In a constrained economy where cash flow and resilience are paramount, this is an unsustainable position.

The strategic response lies in bringing supply chain thinking into the heart of portfolio decisions. Commercial teams must understand that every new SKU is not just a marketing initiative but a supply chain commitment. Cross-functional processes are necessary to evaluate proposed launches against a comprehensive set of criteria, including the impact on the supply chain. Regular reviews of the existing portfolio should identify candidates for rationalisation, pruning back the long tail to release resources and capacity. The prize is not only lower cost but also greater agility, as a less cluttered supply chain can respond more quickly to genuine changes in demand.

Product portfolio complexity and supply chain planning are inseparable. To manage one requires mastery of the other. Organisations that succeed will be those that balance customer choice with operational simplicity, applying discipline to growth strategies and harnessing technology to enhance visibility and responsiveness. In doing so, they will not only improve efficiency but also build more resilient or anti-fragile supply chains that can thrive in the face of uncertainty.

By David Food

Keywords: Culture, Leadership, Supply Chain

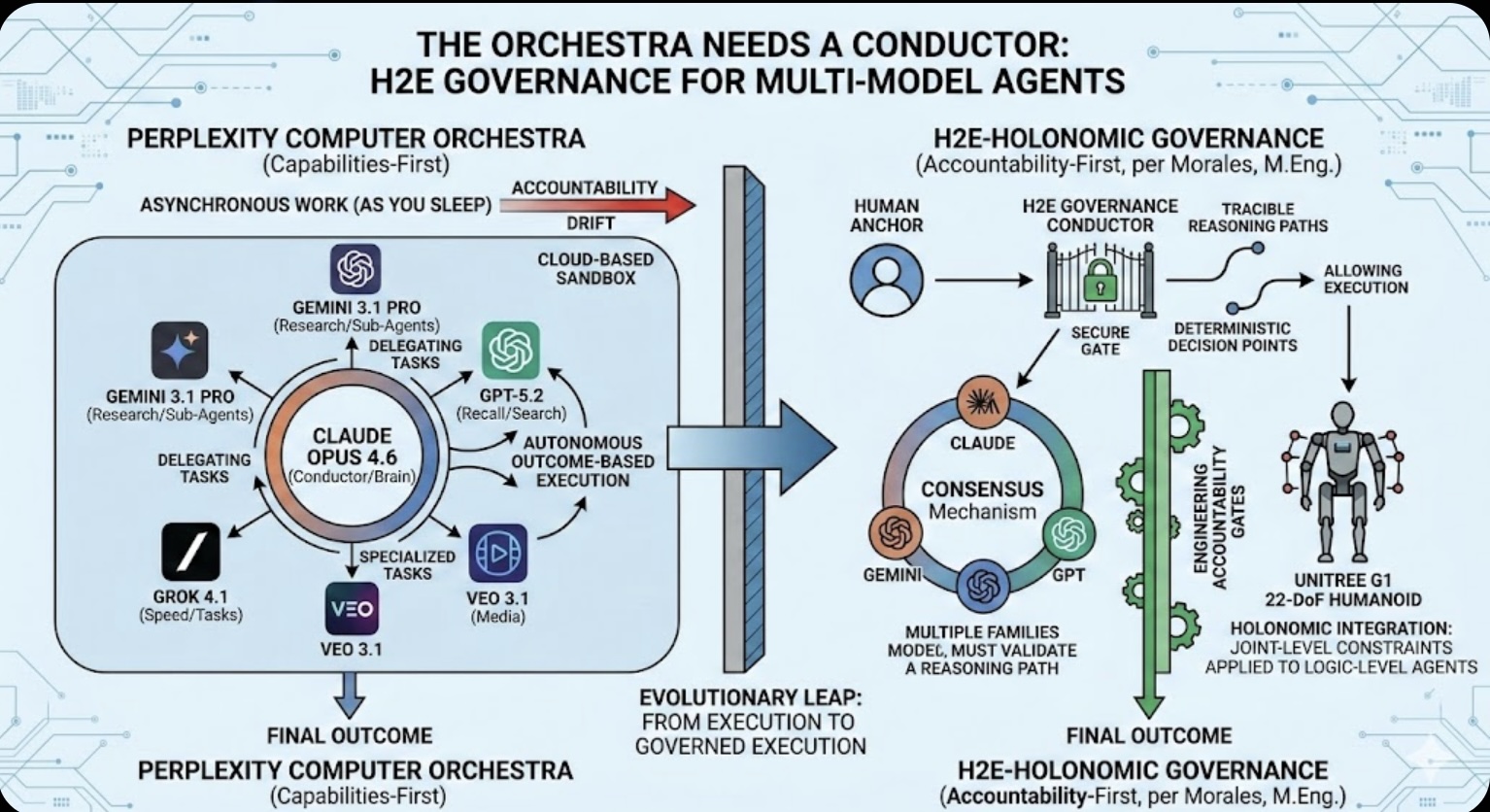

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

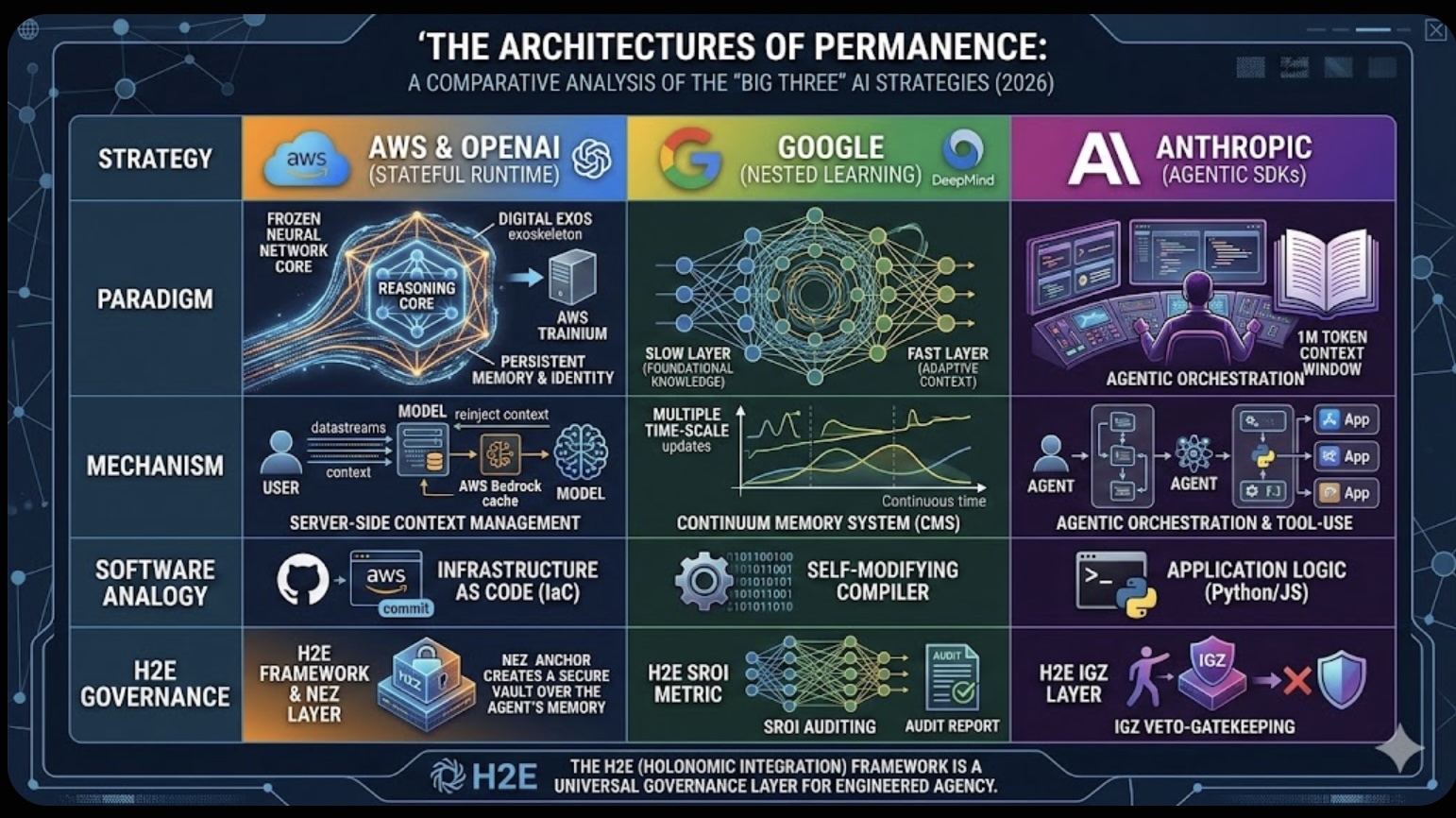

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

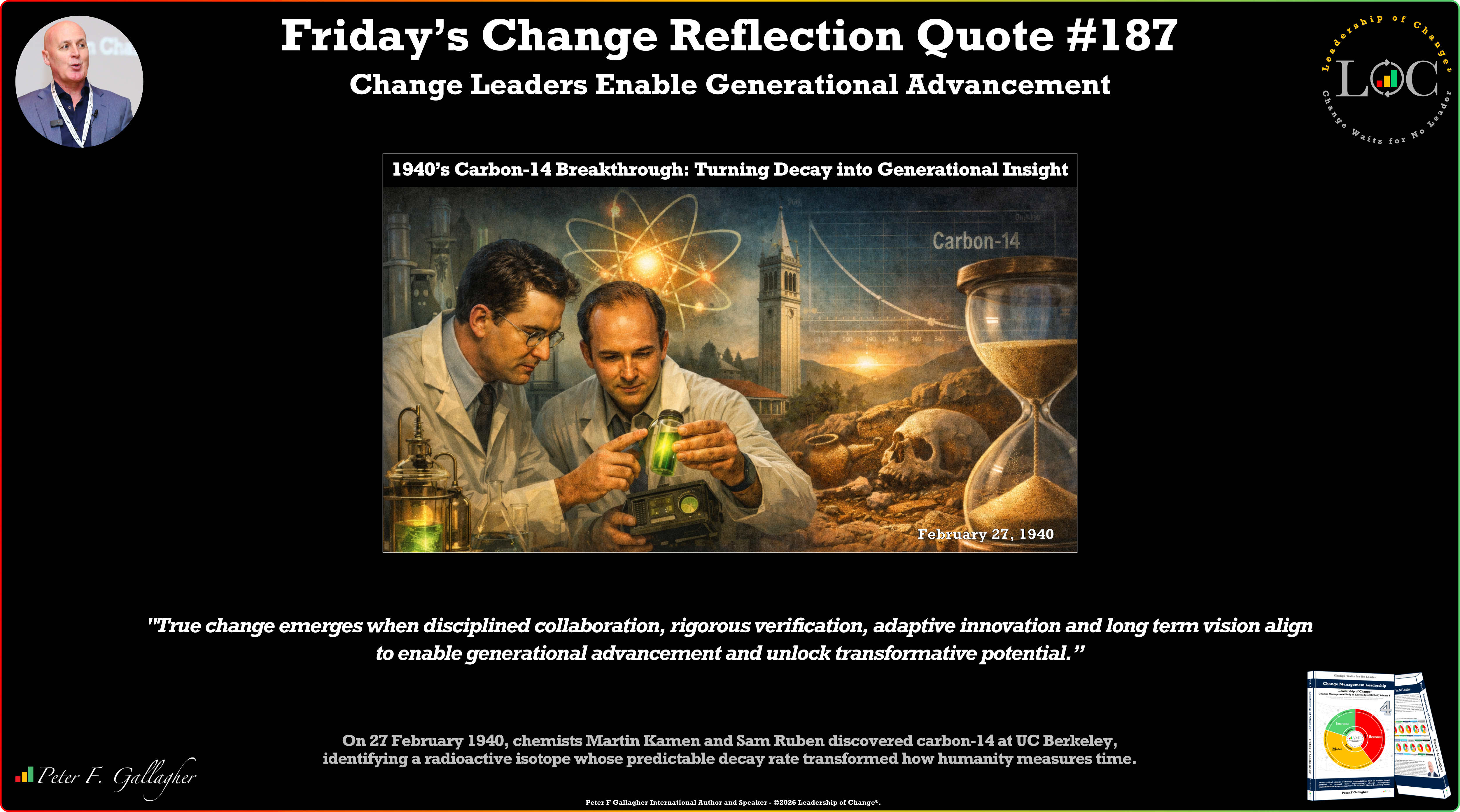

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026