Mar25

Disasters like the COVID-19 pandemic can wreak havoc on even the biggest of a company’s business. Even when your employees and office space are secure, the difference in a time of calamity lies in having a secure and resilient supply chain. In this article, I explore how the direct competition between brands is no longer relevant, and why the only competition that remains is between the companies’ supply chains. I will also take a look at different ways that leaders can employ to build secure resilient supply chains for their businesses.

When the news stories related to the pandemic started breaking on the internet, none of us could have realized the massive scale of the calamity. Given that such a disaster only happens once in a century, we can be forgiven for that. However, what we can’t forgive ourselves for is putting all the eggs in one basket when it comes to securing our business supplies.

The recent disruption of global business supply chains is mostly due to them being either concentrated in a single geographic area or following just-in-time manufacturing and lean production strategies to cut costs. Such businesses now find themselves in a precarious situation with a noticeable shift in the customer consumption patterns, where purchases are now more inclined towards local availability, followed by how responsibly the brand behaves, as against the earlier considerations of price or favorite brand/product.

While the saying goes that a chain is as strong as its weakest link, the same stands true for any supply chain. The impact of the COVID-19 crisis on supply chains can’t be more stressed. According to a recent McKinsey survey of senior-level supply chain executives, the study found that 73% of businesses that were surveyed had encountered issues with their suppliers, while 75% faced issues with production and distribution; 100% of the respondents in food consumer-goods industries had encountered production and distribution problems.

A separate IDC survey on "Supply Chain Agility in the Pharmaceutical Industry" found that 46% of respondents had faced drug shortages during the pandemic, while 70% agreed that their supply chain was very vulnerable or facing more problems with the continuation of the pandemic. 65% of the respondents in the survey also reported that they could no longer accurately plan supply and had lost faith in their demand forecasts, and a stark 43% of respondents lacked the necessary agility and redundancy to survive major business disruptions.

With businesses in the past few years moving towards globalization, they are facing increasing challenges in terms of acquiring customers, onboarding workers and vendors, finding partners and suppliers, and ensuring continuity of business in the pandemic.

Today the biggest question that all manufacturers need to answer is — Which strategies should they employ to mitigate the disruption risks for supply chains? And where should organizations start?

Here is my handpicked 10-point approach for any such business looking to ensure continuity of service by building a secure and resilient supply chain:

To be resilient, a business needs to develop a balance between just-in-time manufacturing and lean production strategies and developing AI and analytics-powered early warning system models within supply chain risk assessment tools. Such tools can offer complete visibility across all levels and can sound off alarms whenever they identify any slowdown, interruption, or any other issue. Early warning systems based on a well-defined predictive model, KPI, and leading indicators can also help businesses identify their weak links in the supply chain, so they can plan around it by building redundancies.

While in the past two decades businesses have built their supply chains around cost optimization, the current pandemic has shown that this may not be the best practice. Lower levels of available inventory and disrupted supply chains have driven many businesses into the ground.

In the next few years, businesses should focus on simplifying their product portfolio and diversify the manufacturing capability (aspects like different locations, different suppliers) so that they can keep their manufacturing and supply chain differentiated. The ability to operate alternative sites for manufacturing and securing supplies from different suppliers may add some extra (and might require some discipline in quality assurance) cost but provides insurance against any disruption.

Businesses need to create a much more agile supply chain. This can be done by collaborating and sharing data between all stakeholders involved in building the supply chain. Both agility and resiliency can be improved by new near real-time B2B integration and sharing data down the supply chain. Especially with the Tier 2 and 3 suppliers, providing them more visibility of plans can allow.

Creating a coherent digital strategy to combine global and local supply chain strategies, by using insights from data to derive competitive advantage and to achieve business outcomes, should become the new normal.

The main issue with the pandemic has been restricted geographical access. Thus, I would like to see a much fresher approach by businesses to explore and identify new commercial strategies to fuel growth in areas that were left untouched before the present pandemic.

COVID-19 has highlighted many vulnerabilities in the conventional strategies being utilized for building supply chains. Businesses need to work on a more collaborative model and redefine the contracts with their suppliers, vendors, and partner ecosystem. Contracts need to allow for a new set of KPI, location independence, risk and rewards mechanism, elasticity in supply, cash flow, payment terms, and most importantly redundant paths for a single point of failure in the chain including alternate routing.

With things not remaining the same as before, businesses need to invest more in restructuring their last-mile delivery channels, via identifying new ones — such as order online, pickup in-store, curbside pickup, delivery using robots and drones.

Organizations should centralize any information necessary for the core functioning of the vendors and supply chains to prevent any eventuality where the concerned managers may not be available. They should also look to localize various vendor relationships and delegate decisions to local teams.

Businesses are being crippled by losses as insurance providers are introducing new insurance policy exclusions. They need to understand that traditional insurance is not adequate when dealing with pandemic-related business interruptions. The best insurance in the future against incurring any such losses is prevention itself. Building resilience-as-a-service into the system is now a necessity.

I would rather take it to next level and recommend that businesses apply the chaos testing model for pandemic readiness. Businesses need to test and investigate their pandemic readiness regularly very similar to the chaos testing frameworks used in the IT application domain. They need to implement a workplace pandemic preparedness plan in sync with their continuity plans.

A data-driven reinvention of business practices will be critical in post-pandemic growth. Businesses will need to embrace the use of responsible AI capabilities to recover and return to their pre-pandemic growth plans. Businesses would need to leverage AI across their supply chain, business processes, customer experience, and employee experience. Who does it more professionally and ethically will be the key.

Businesses should adopt the use of digital data and insights more extensively as part of their strategy. Cross-platform digitization can help them understand things clearer and faster to predict and prevent unnecessary blockages in their supply chain and vendor management structures.

Leaders need to realize the importance of system thinking as the missing skill-set in this whole pandemic scenario. Businesses should utilize systems thinking to look at a holistic picture of all the interconnected ecosystems. They will then be able to predict evolving complexities and the risks associated with them.

To be successful in the future, businesses need to define more flexible, adaptive, and resilient processes and establish multi-disciplinary teams to define new processes and innovate for new products.

As business stakeholders are redefining products, services for new customer experiences, IT needs to catch up with the fast pace of delivering new applications and new functional requirements. Enterprises need to take a cloud-first approach. The cloud-first approach would allow for faster innovation with lower cost and allow enterprises to focus on core functionality instead of building resilient IT platforms.

As organizations are looking to scale up their technological capabilities, including the IT and cloud infrastructure, to be ready for the new normal. Some of the areas that I would recommend reducing technology debt are:

Developing a remote working strategy for your business can ensure that everyone can securely access the tools they would require to work remotely, including any access to business systems — including HR, ERP, payroll, CRM, unified communication (UC), and collaboration tools, file storage, and email. At the same time, setting up an omnichannel workforce management system should also be a priority, with an increased focus on employing digital solutions to tackle the new challenges.

Increasingly, companies are discovering that remote working scenario has created a mismatch between the type of skills that are needed and what their employees have. As business leaders turn to automation, digitization, and value data extraction, the workforce should be able to complement the value that is being added by the new technology.

While businesses have been automating processes for efficiency in operations, they need to do so for every department in a post-COVID world. Utilizing composite AI to re-imagine the ways of doing business while factoring in various productivity scenarios will be an in-demand strategy in the new world.

For businesses to make remote working a more responsible process, the HR teams have to come up with their own set of remote working procedures that can communicate organizational expectations to employees and also ensure any upskilling that may be required on their part. HR and IT teams need to work in more cohesion in the new world.

In a new interconnected world, to drive realistic customer demand and to sustain continuity of business, organizations should look to create a ‘digital twin’ of the entire supply chain (or of key processes) to simulate and adjust for the developing scenarios.

Also, increased dependence on subscription-based models should help cater to evolving customer demands. In short, businesses need to shift to a product mindset and leverage technology as an enabler to define new services and subscription models.

Businesses need to ensure that their cybersecurity teams are all geared up to protect their data, applications, and resources from any kind of threats or to respond to alerts. As remote working finds a more comprehensive place in the business ecosystem, CISOs must draft new security policies (for data security, network security, app security, and remote wipe out) to accommodate for the increase in telework.

While globalization was the talk of the town in the '90s, I feel that eventually, global supply chains may end up becoming a victim of their own success. As businesses were over-reliant on strategies focused on cutting costs, they had increasingly become less flexible and resilient with their supply chain structures. This needs to change, and the ones to adapt quickly will be the new market leaders.

Keywords: Business Strategy, Business Continuity, COVID19

Lateral Moves: The Most Overlooked Succession Strategy in Companies

Lateral Moves: The Most Overlooked Succession Strategy in Companies The Asset Play: Timing, Structure & Global Arbitrage

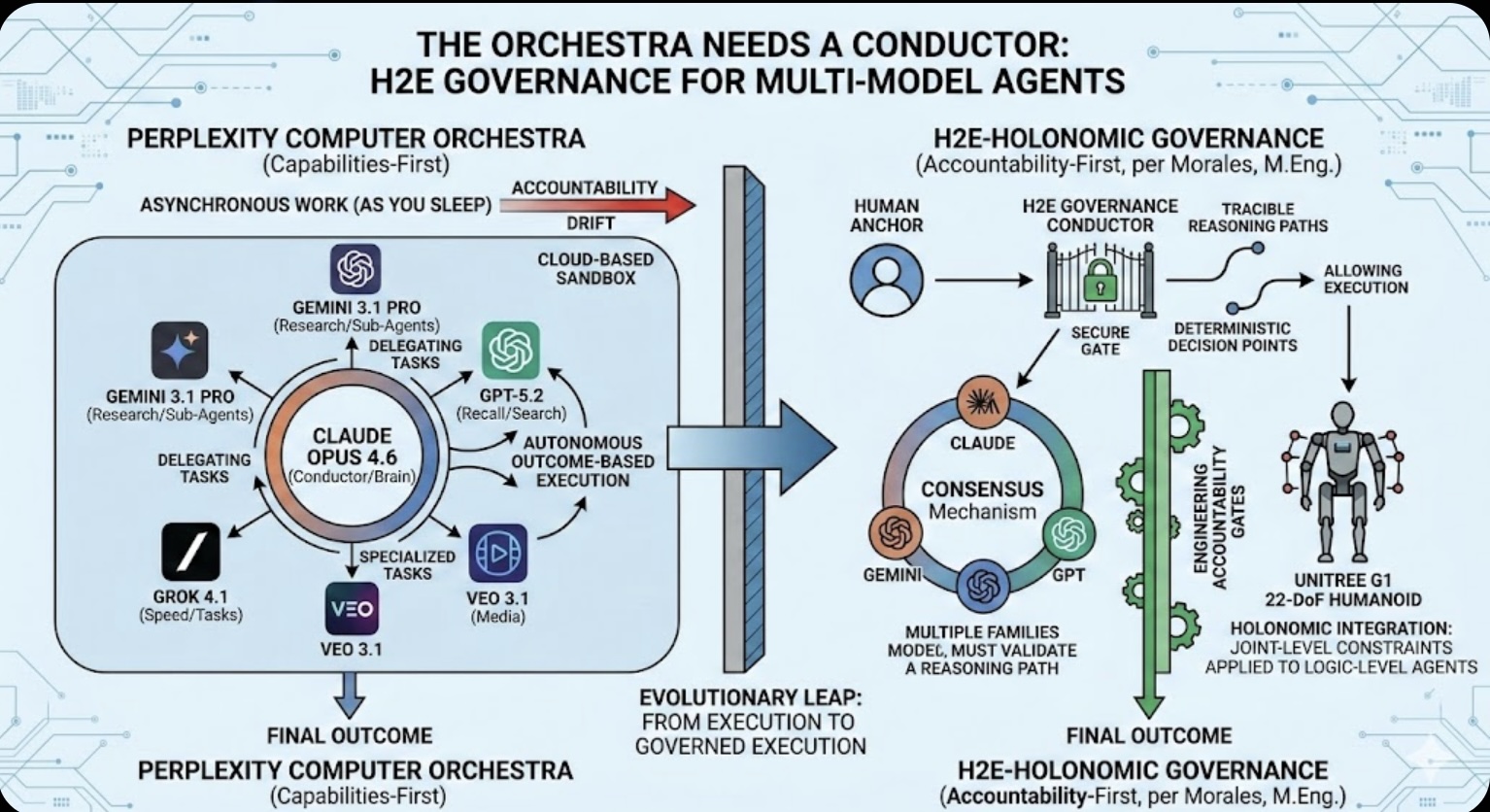

The Asset Play: Timing, Structure & Global Arbitrage  The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

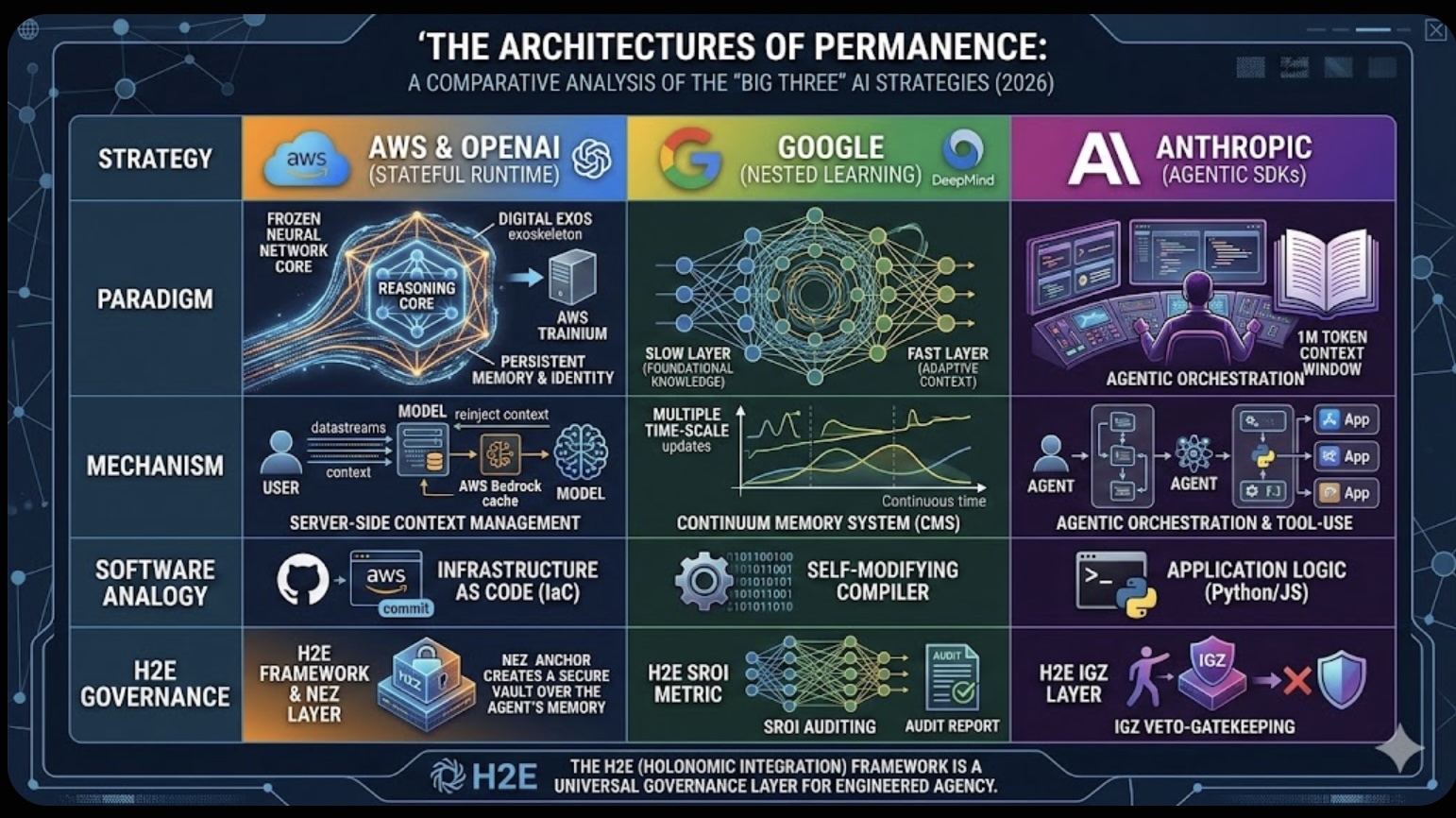

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)