Mar27

We’ve spent years fine-tuning the rhythms of supply chains, applying digital tools, data, and policy nudges to reduce carbon, optimise inventory, and electrify logistics. Yet one of the most urgent environmental flashpoints remains stubbornly neglected, wrapped in complexity and often exported far from sight: electronic waste.

Every cable, phone, laptop, server, industrial controller, when it reaches the end of its useful life, joins a growing mountain of discarded technology. E-waste is now the fastest-growing solid waste stream in the world. And it's not just about volume. It's about what’s inside: rare earths, heavy metals, flame retardants. Stuff that’s hazardous to extract, toxic to dispose of, and increasingly hard to source.

In episode 60 of the Sustainable Supply Chain podcast, I sat down with Kenny McGee, founder and CEO of Component Sense, to discuss what’s really happening on the ground with global e-waste, and what it means for supply chain professionals and sustainability leaders. Kenny shared insights from a recent trip to Agbogbloshie in Accra, Ghana, formerly the world’s largest e-waste dump site. What he found there was equal parts inspiring and devastating.

But let’s not get ahead of ourselves.

Let’s set the context. According to the UN’s Global E-Waste Monitor, the world generated over 62 million tonnes of e-waste in 2022. That’s a 20% increase over five years, with projections putting us on track for 82 million tonnes by 2030. Only 17.4% of that waste is formally documented as collected and recycled.

Why so little?

Because e-waste, more than any other category of waste, is mired in complexity. It straddles legality, informality, and outright criminality. It’s difficult to sort, expensive to recycle properly, and often shipped illegally or semi-legally to countries with weaker environmental regulations under the label of “used goods.”

And here's the kicker: it’s not all waste. Much of it is perfectly usable equipment, or equipment that could be refurbished or repurposed. But in a system designed to prioritise throughput, not longevity, even minor faults often mean the scrap heap.

Kenny’s trip to Agbogbloshie was not the typical sustainability mission of metrics and dashboards. It was an attempt to trace the physical reality of the “end of life” phase of electronics.

What he found is a system of extraordinary resourcefulness built on unbearable trade-offs. Second-hand traders in Ghana buy shipping containers full of discarded electronics, ostensibly tested and working. But in reality, Kenny says, only around 20% of the goods function on arrival. The rest? They enter a cascading informal repair and salvage economy.

Technicians, many of them teenagers tear down, scavenge, resell, and in many cases, burn. Circuit boards are stripped of copper and gold. Cables are incinerated to get at the wire inside, using polystyrene from old fridges to boost the flames. The smoke is dense. Toxic. Relentless. Burning plastic infused with brominated flame retardants is a regular part of daily life.

And this isn’t happening on some remote industrial site. It’s happening in people’s front yards. Right next to their bedrooms. Children grow up with this as their air, their soil, their normal.

All of this from equipment that was supposedly “recycled” in Europe.

The circular economy sounds great in theory. Keep products and materials in use. Design for disassembly. Refurbish and reuse.

But it breaks down when the loop crosses borders.

By EU law, it’s illegal to export e-waste to developing countries. And yet, as the Basel Action Network and other watchdogs have shown, thousands of tonnes slip through every year disguised as “used goods.” That loophole, deliberate or not, transforms a circular process into a linear one that ends in uncontrolled incineration, contamination, and exploitation.

Kenny traced some of these downstream paths. He saw British and Chinese companies operating in Ghana, buying circuit boards, stripping them of components, and shipping them back to Asia. He found high levels of secrecy, a lack of regulatory oversight, and a clear mismatch between sustainability rhetoric and material practice.

Here’s the brutal paradox: for many in Ghana, e-waste is not just pollution. It’s livelihood.

An estimated 40,000 to 140,000 people live in and around the Agbogbloshie site. Some work in repairs. Others in salvage. Others in micro-trading - recycling cables, reselling components, or running makeshift TV halls that stream Champions League matches on salvaged screens.

Shut down the supply of e-waste, and you're not just cleaning up a dumpsite. You're cutting off entire communities from their only source of income.

That’s what makes the e-waste challenge so thorny. It’s not simply a case of enforcement or clean-up. It’s a case of creating real alternatives. Replacing unsafe work with safe work. Preserving livelihoods without poisoning the air.

As Kenny put it, “my goal was always to have the adults working in quality jobs and the kids at school.” But achieving that, he quickly realised, isn’t a matter of intention - it’s a matter of system-wide transformation.

The design stage of electronics is where the greatest influence lies. And the message is clear: we need devices that are easier to repair, easier to disassemble, and longer lasting by default.

Kenny’s company, Component Sense, already works with manufacturers to repurpose unused or obsolete components. They’re tackling overproduction and inventory waste. But as he noted in our conversation, even industrial equipment could be made modular: upgrade the technology, reuse the housing. Don’t redesign everything from scratch.

The same applies to consumer electronics. We need:

Right to repair legislation is gaining traction in the EU, US, and beyond. But legislation alone won’t solve it. We need incentives that make repair the smart economic choice - not just the moral one.

And just as importantly, we need supply chains that support transparency beyond Tier 1. That means tracking not only how products are made, but how they’re unmade. Where they go. Who handles them. And under what conditions.

If you’re in supply chain, procurement, or sustainability, you’re in a position of leverage.

And personally? Resist the upgrade treadmill. That new phone, laptop, or smart speaker might come with a green sticker - but it comes at a cost, too.

Extending the life of your electronics is one of the simplest and most impactful sustainability decisions you can make.

What struck me most in speaking to Kenny was just how embedded this issue is in supply chains. E-waste isn’t a downstream problem. It’s an upstream design flaw, a midstream inventory failure, and a downstream regulatory gap.

It’s the shadow side of global logistics - the reverse flow that rarely gets tracked, let alone optimised.

But as supply chain professionals, we can help rewrite that story. We already understand flows, data, optimisation. Now we need to apply that same thinking to obsolescence, repairability, and reuse.

Not to push the problem further afield, but to fix it at the root.

If you want to hear more from Kenny about what he saw in Ghana, how Component Sense is tackling electronic surplus, and what manufacturers can do to be part of the solution, listen to the full episode of the Sustainable Supply Chain podcast:

Repair or Ruin: E-Waste, Informal Economies, and the Role of Manufacturers

Let’s stop calling e-waste a downstream problem. It’s a systems problem. And that makes it a supply chain problem - one we can absolutely begin to solve.

This article was first published on TomRaftery.com. Photo credit Fairphone on Flickr

By Tom Raftery

Keywords: CSR, Supply Chain, Sustainability

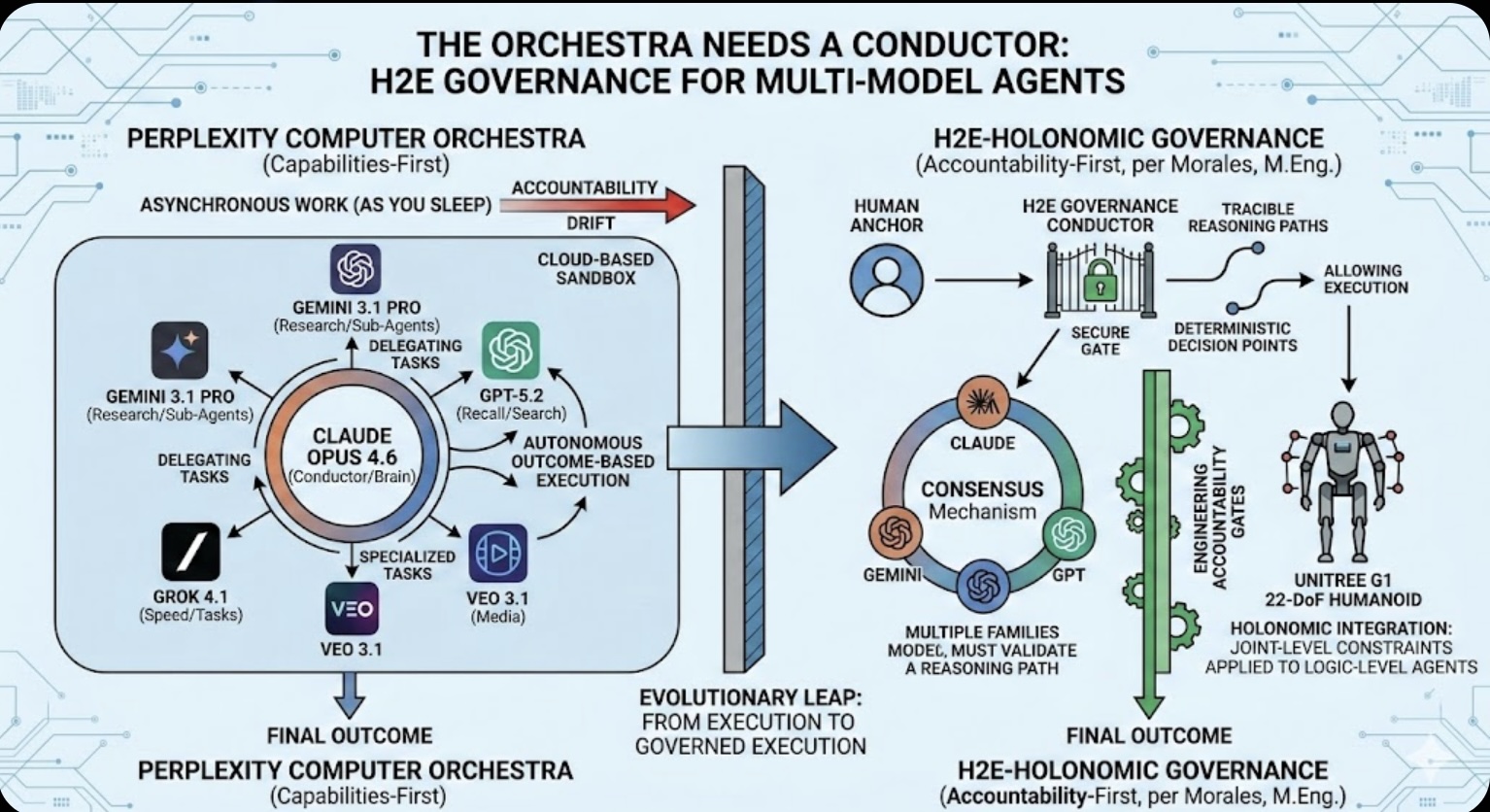

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

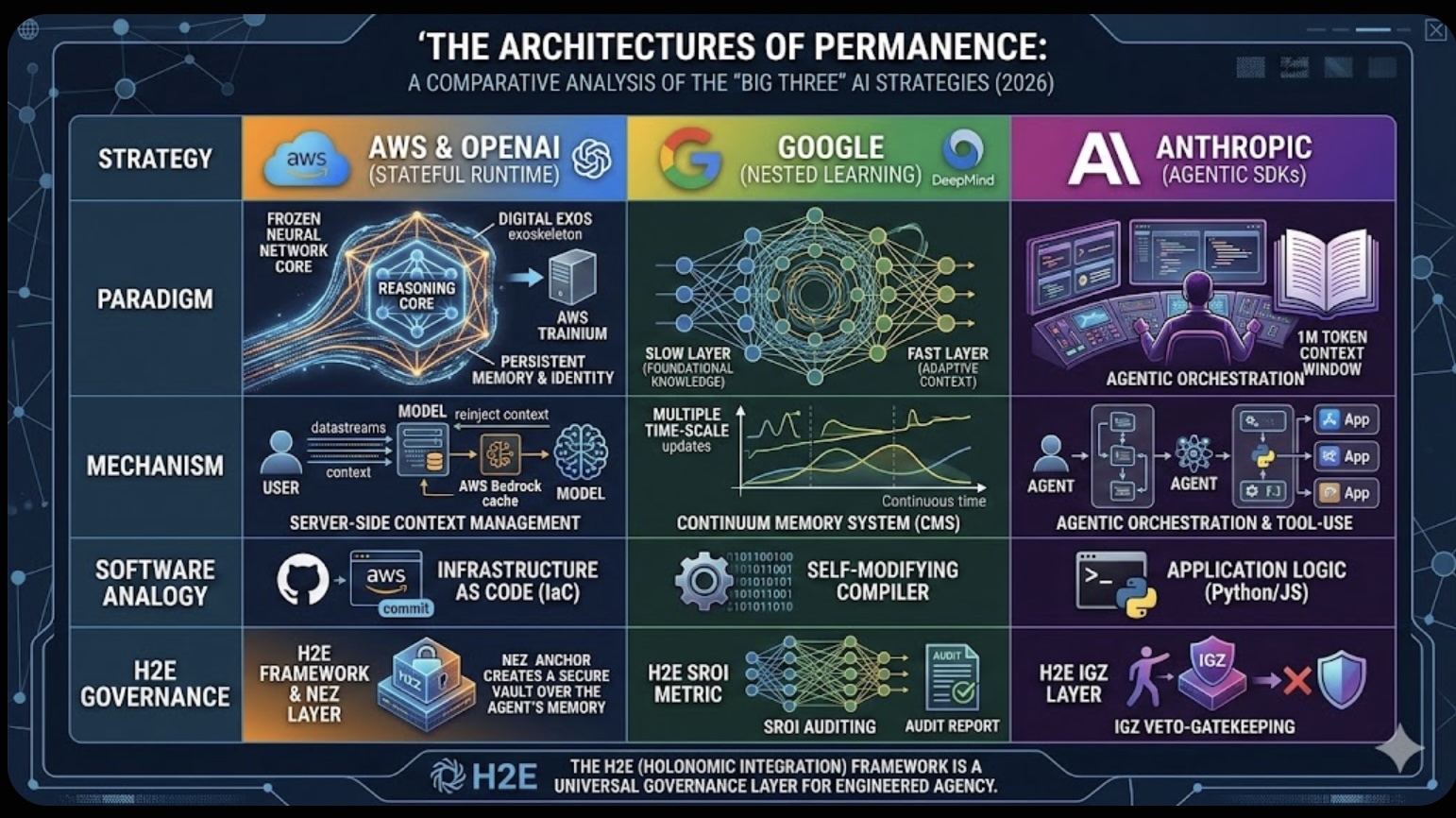

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

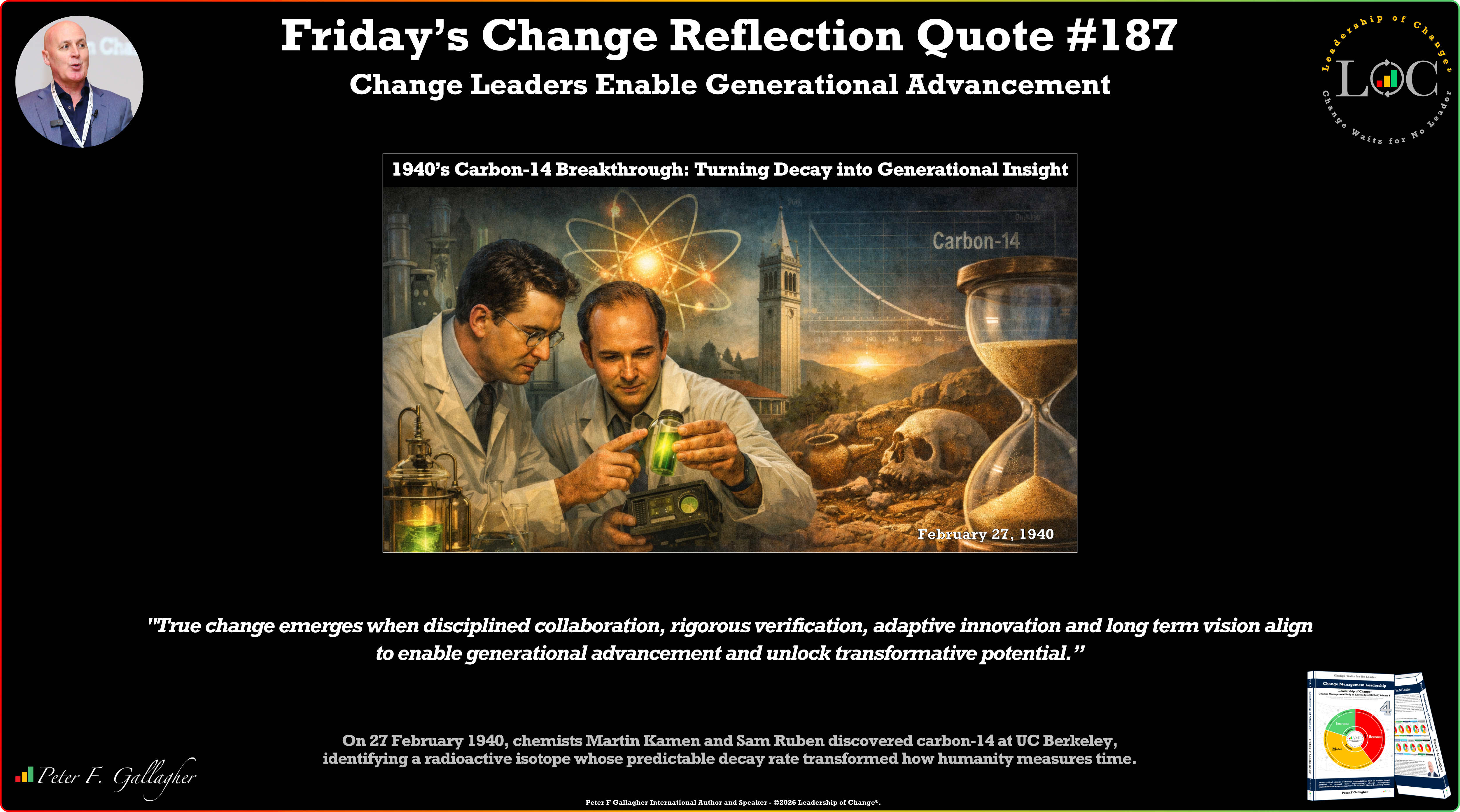

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026