Mar14

The Scooby-Doo Moment

A parting gift from Theresa May’s Government was to legislate in 2019 that all institutions (commercial and public) in the UK must reach Net Zero buy 2050. Net zero means no longer adding to the total amount of greenhouse gases in the atmosphere. The immediate reaction, especially by major industry, to this world-first announcement was akin to the cartoon character Scooby-Doo’s classic reaction of surprise - “huh”. There was a general sense that companies did not see how it could be achieved. The Government, media and the public initially focused its Net Zero targets on transportation and energy generation. For example, the UK Government (i.e., the Civil Service) is clearly fixated on offshore wind (and onshore wind as long as it’s not in England), while in transportation everything is aimed at financial incentives for EV vehicles and funding for charging infrastructure. An area that has not, to date, received as much visibility by the media is the carbon emissions associated with heavy industry. Industrial emissions in Wales are 29% total CO2 emissions and 12% across the entire UK. Across all areas of adoption for technology to reach Net Zero there are two choices: either use current (possibly inefficient or costly) technology or new (unproven but possibly lower cost and more efficient) technology. The former technologies are easier to adopt but possibly inefficient or costly, while the latter option technologies are unproven but possibly lower cost and more efficient. If we need to adopt newer more efficient and economically viable technologies, then we need to demonstrate their viability. Unfortunately, we have less that 30 years to develop, demonstrate, prove and implement new/improved technology.

The Traditional +10 Year TRL Pathway for Technology Adoption

In the 1970’s NASA developed the concept of technology readiness levels (TRL) to provide a method for estimating the maturity of technologies during the acquisition phase of a program. As evolved for general industry and technology, TRL ranges from “1”, which is when “basic principles are observed” to “9” when the “actual system is proven in operational environment”. Ordinarily, to get a technology to TRL 9 it is necessary to need to demonstrate viability of technology it is necessary to de-risk the technology, the economics, and the impact. Regarding the technology, it is necessary to determine not only does it work, but will it impact current production? For the economics it is how much will it cost, and will it impact the consumer? Finally, regarding impact, will it cause industry to change and what is the reliability? The problem with moving from “basic principles” to “proven” is that outside of IT, it takes at least 10-year to move from TRL 1 to 9. Over the last 37 years as an academic, I have started companies in solar energy, oil and gas, water treatment, and PPE, and this 10-year rule is pretty much uniform. Thus, assuming invention to development for a new material, process or system takes 10 years, this now gives <20 years to reach Net Zero. But even after 10 years of traditional research and development, the technology can be deployed, but this does not mean 100% adoption, there is now a rate of widespread adoption that timeframe. In the case of transportation there has been a 3 to 5 years renewal cycle, but in heavy industry the timeframe for adoption of changing processes can be over 10 years. Finally, local authority planning and permitting can further delay implementation. So, with all these issues, there is less than 10 years to get 100% adoption to ensure Net Zero targets are reached. It is clear therefore, that it is too late for studies… now is the time for action. I would also say it is too late for basic research, it is development and deployment that should be the focus of UK Government.

Unique Approach to Validation New Net Zero Technology

Two years prior to the 2019 announcement of Net Zero, I approached the Welsh Government with the idea that industrial decarbonization was going to be required to ensure the heavy industry in Wales (particularly South Wales) was to continue as the major employer and economic driver. Instead of the usual academic project that would be research as usual with no planned exit strategy (other than getting the next grant), I proposed an alternative approach. The RICE Project was created as a route for transforming low to medium TRL technology to TRL 8 or 9 in one step, then running the technology on their industrial site integrated with the host industrial process. Six technologies were “invested in”: a new style of green hydrogen electrolyser; a biorefinery with downstream processing; a PSA system to test new solid adsorbents; a fermentation system for conversion of blast furnace gas into acetates for polymer production; heat to hydrogen; heat, hydrogen and their efficient use. Of these two succeeded the to reach TRL 8/9 and operate. So, 33% success rate greater than 20% success of Venture Capital. A new green hydrogen electrolyser developed by Charlie Dunnill, was low cost but unlike commercial units does not require water purification, is not degraded by switching on and off making it ideal for wind and solar power and can accept multiple voltage inputs simultaneously. It operated at Hansen cement plant injecting hydrogen into their furnace for 3 years, while additional commercial units were installed elsewhere. The design is ideal for small scale needs (lower than 500 kW which is appropriate for many potential hydrogen users) and it is being commercialized by Kronos here in UK, EU and Africa. The Integrated Bio-refinery, developed by Darren Oatley-Radcliffe, was constructed on Vale Clydach nickel refinery taking CO2 into a large-scale algae reactor system on a COMAH Tier 1 site. Unlike other systems, the Integrated Bio-refinery concept meant that the algae produced was processed to extract out protein, omega lipids, carbohydrates, and high value dye derivatives. It operated consuming CO2 for 3 years; at the end of the project the infrastructure was taken over by Algae Products International who are now selling products to a range of industries.

But how do we encourage future success in technology growth?

The key achievements of the RICE project were that it installed multiple high TRL demonstrators on COMAH Tier 1 sites (predating the UK Government Cluster), which were operational for >3 years (including during COVID), and have led to creation of commercial entities. Most important was the demonstration that creating value from CO2 is possible. Despite the success and future potential there were some lessons learnt that should be considered by Government for any current or future clusters and projects.

The Ikea Model for Technology Evaluation

DESNZ and other government departments should use the concepts developed by the RICE Project in implementing TRL 8/9 technology inside a 5-year project leading to commercial success at an investment of approx. £10 million. Given that rapid low-cost deployment of CCUS is the one of the biggest challenges to achieving Net Zero targets. This leads to the proposal of an “Ikea” model for technology validation. Ikea has not only perfected the “mouse trap school of architecture” (you must walk past everything in the store just to buy a light bulb!), but it also provides a single location to immerse yourself in a model version of your needs. You want a new bedroom suite? You can go into each model and sit on the bed, try the wardrobe, test the function of draws. Everything is set up in an environment like where you will deploy the system. So why is this relevant? Industry is conservative when adopting new technology. As noted above industry needs to have any new technology or process de-risked before it invests. One of the requirements of the hosts of the RICE project was that each demonstration/pilot unit should be accessible to any other company, government agency or interested party. Thus, during the project we had visitors from UK and globally to the units, some were engaged enough to start talking about their own adoption. We were able to show that HAZOP studies had been done for placement on a COMAH Tier 1 site that gave immediate comfort around Health and Safety, while the very fact that operation was integrated with the host company satisfied potential users that it would not disrupt their own process. So how would the Ikea model work in the future? Where does the Government come in? The UK Government fund projects, from Innovate UK grants to £22 billion for offshore CCUS clusters, when it does this there should be a clause in the funding contract that the recipient must implement pilot units from SMEs and provide access to other companies. The host would have to carry only minimum cost such as rates, water, electricity and connection (e.g., of a flue gas stream in the case of CCU), the cost of the pilot unit and associated assets would be covered by the SME via either investment of Innovate UK funding. The host industry would benefit from on-site trials of technology it would otherwise not have access to, as well as potential 1st adopter advantage. Most importantly, the host would benefit from the PR. This was exactly the outcome of the biorefinery on Vale’s Clydach Refinery, where both the Project and Vale had visitors from industry, government and even schools. But what if a company refuses to integrate SMEs and new technology? Simple. They do not receive the Government funding. We require many more pre-conditions to funding such as drug free workplace and anti-slavery regulations. Why should this be any different?

Final thoughts

Some final thoughts on decarbonization challenges. Decarbonization should not be a financial burden on the consumer via either tax or cost of materials. The process should be financially viable creating value. Do not assume that one solution will solve the problem, every ton of CO2 reduced, captured or utilized by multiple processes is just as good as one large solution, but the risk of the latter is much higher. Instead of a single process, the lessons learnt from the oil industry of valorization of the entire barrel of oil through multiple uses shows that the economics of decarbonization at scale can only achieved by implementing a system comprising the integration of symbiotic processes: one person’s waste is another person’s feed. Finally, while it is difficult to raise capital for new technology, it may appear odd, but it is easier to raise £100,000,000 that £1,000,000, which makes it difficult for SMEs to advance their technology, thus creating a symbiotic integration of multiple technologies de-risk the financial model.

Keywords: Climate Change, Renewable Energy, Sustainability

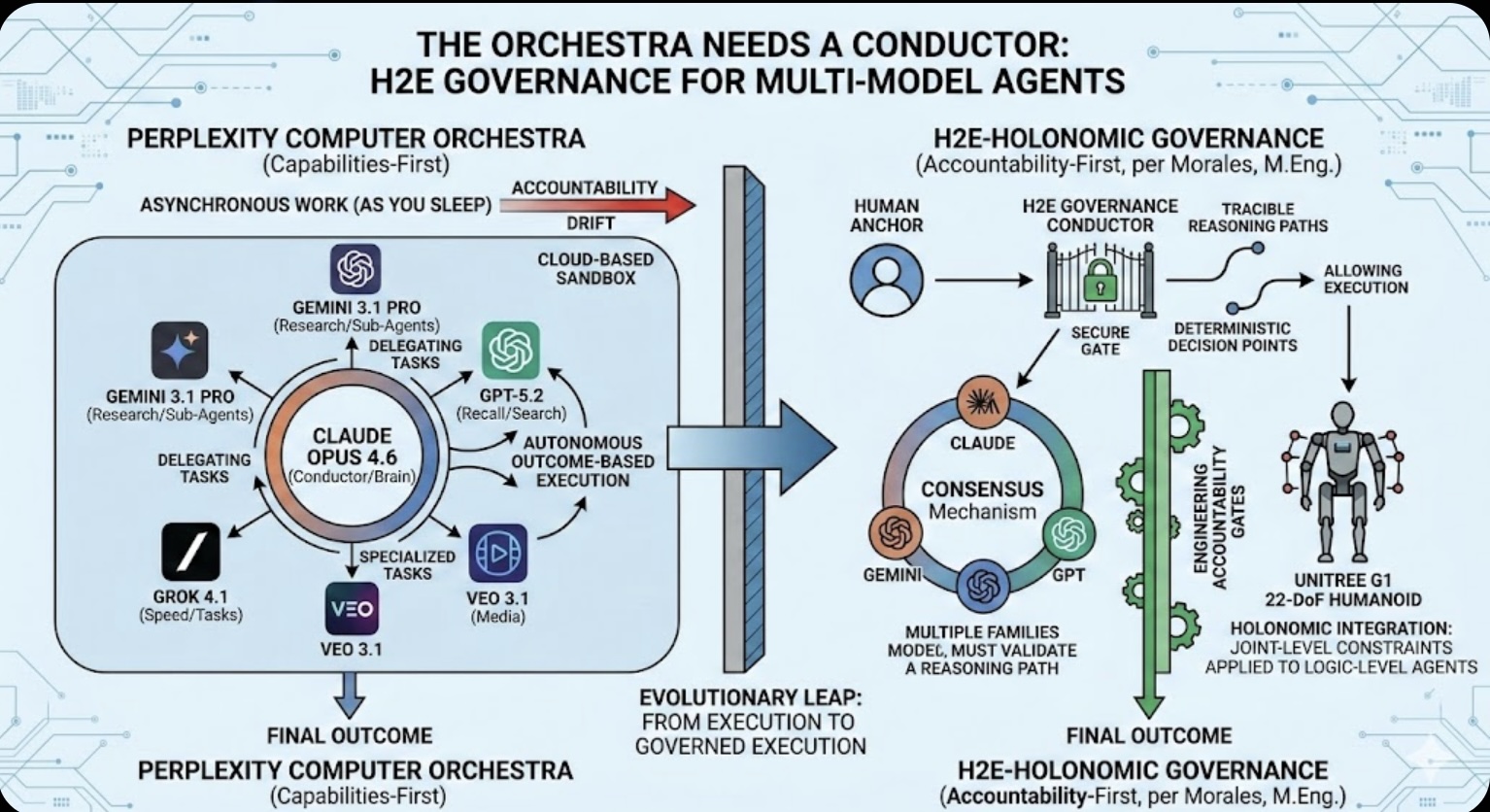

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance

The Orchestra Needs a Conductor: Why Multi-Model Agents Require H2E Governance The Role of Memory in Modern-day Business

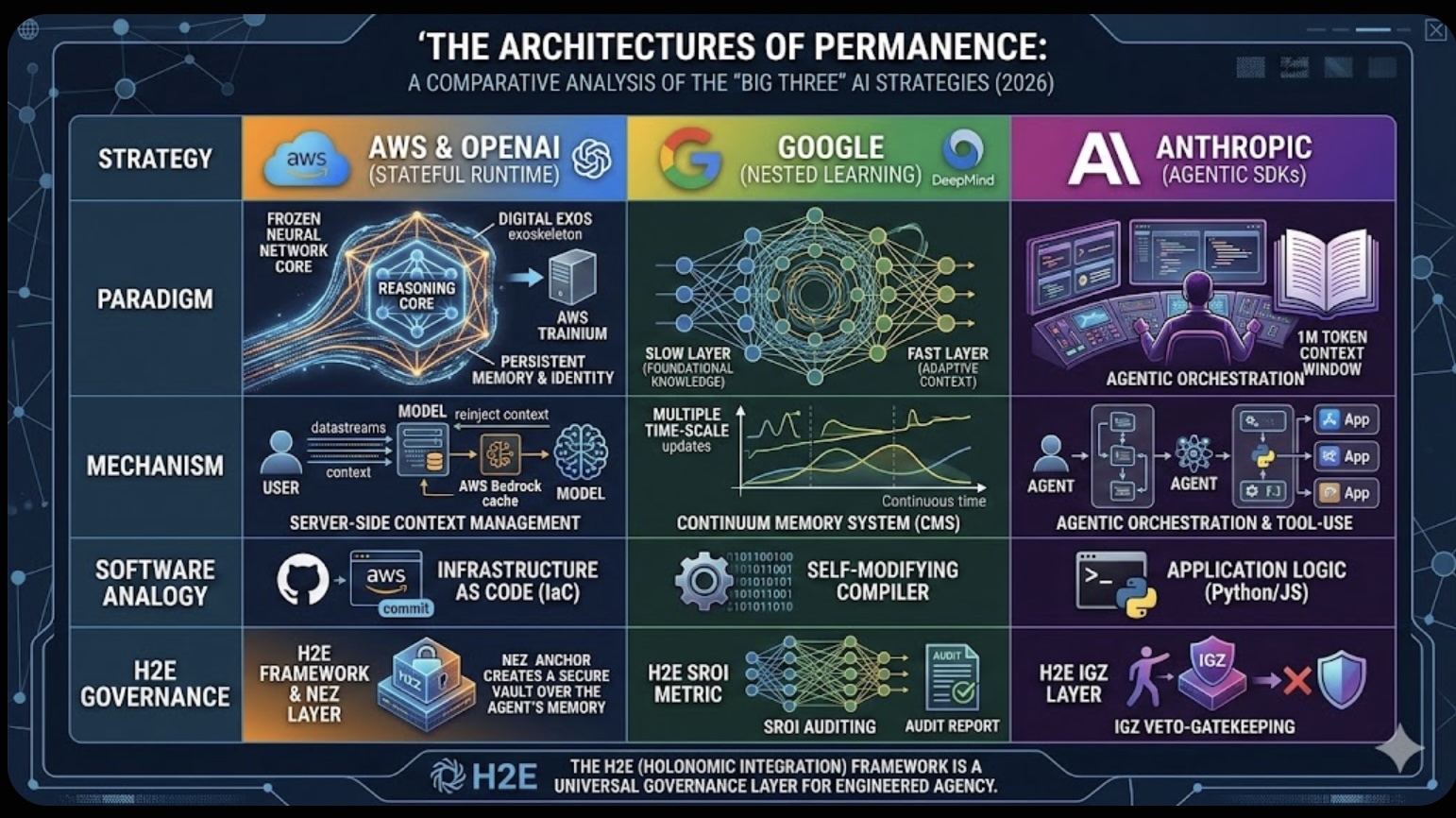

The Role of Memory in Modern-day Business The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026)

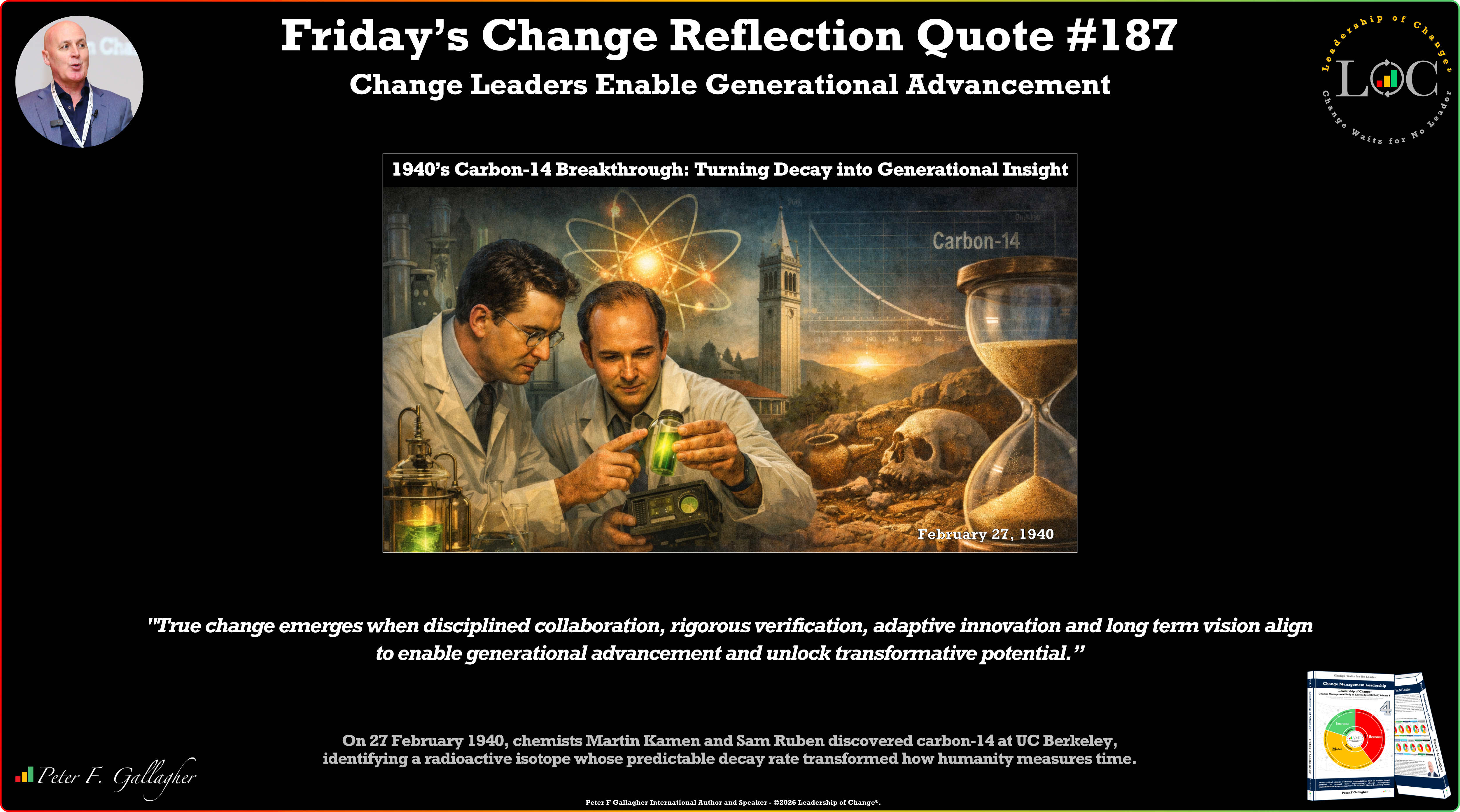

The Architectures of Permanence: A Comparative Analysis of the "Big Three" AI Strategies (2026) Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement

Friday’s Change Reflection Quote - Leadership of Change - Change Leaders Enable Generational Advancement The Corix Partners Friday Reading List - February 27, 2026

The Corix Partners Friday Reading List - February 27, 2026